8

Installation Note E6650-90013

Installation Procedure

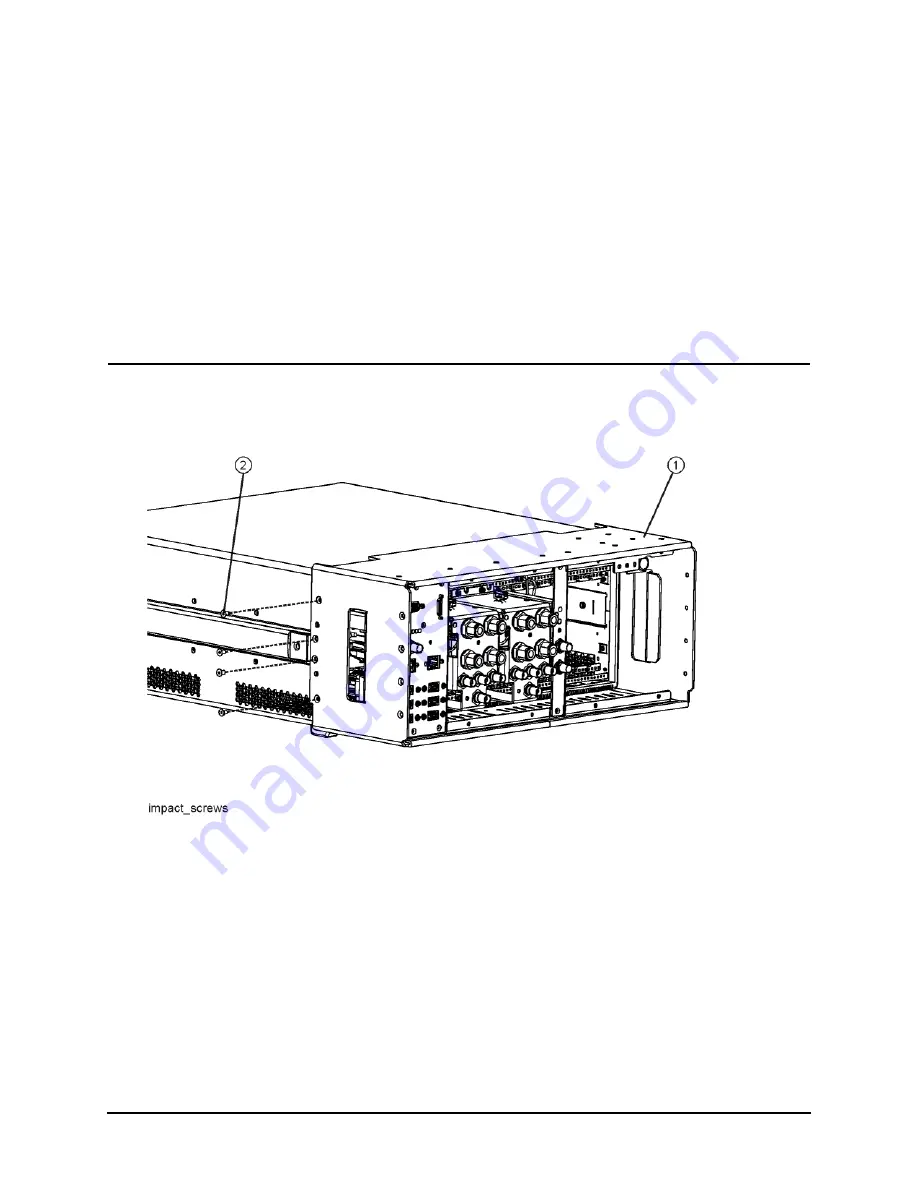

5.

. Remove the 4 screws

(2)

on each side of the Impact cover

(1)

. This will

disconnect it from the chassis frame. Slide the Impact cover away from the chassis and over

the Controller and Reference panels which were disconnected in the previous step.

NOTE

The Controller panel cover panel and Reference panel do not need to be

removed with the Impact cover. The Controller panel and the Reference panel

may be tilted in and the Impact cover slipped around them.

Removal of the Impact cover over the Controller panel requires you to move

the Impact cover towards the controller. This will allow you to tilt the

Controller sub-panel. See

Figure 4

Impact Cover Screws