2 - INTRODUCING THE PRODUCT

3 - PRELIMINARY CHECKS

Before installing the product, perform the following checks and in-

spections:

check that the barrier is suitable for automation;

the weight and size of the barrier must be within the operating limits

high acidity or salinity or nearby heat sources might cause the pro-

duct to malfunction;

in case of extreme weather conditions (e.g. snow, ice, wide tempe-

rature variations or high temperatures), friction may increase, cau-

sing a corresponding rise in the force needed to operate the system;

the starting torque may therefore exceed that required in normal

conditions;

check that when operated by hand the barrier moves smoothly wi-

thout any areas of greater friction or derailment risk;

check that the barrier is well balanced and will therefore remain sta-

tionery when released in any position;

check that the electricity supply line to which the product is to be

connected is suitably earthed and protected by an overload and dif-

ferential safety breaker device;

the system power supply line must include a circuit breaker device

with a contact gap allowing complete disconnection in the condi-

ensure that all the material used for installation complies with the

relevant regulatory standards.

TECHNICAL SPECIFICATIONS

900ALT242K

900ALT624K

Torque

200 Nm

250 Nm

Temporary service

80 %

80 %

Opening time

3.5 sec

6/*12 sec

Control unit

14A

14A

Power supply

Vac (Vdc) 230 (24)

Vac (Vdc) 230 (24)

Motor absorption

1.3 A

1.3 A

Input power

300 W

300 W

Integrated lights

si

si

Protection class

IP 54

IP 54

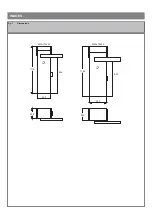

Dimensions (L-P-H)

360-220-1110 mm

450-280-1188 mm

Weight

47 Kg

67 Kg

Operating temperature

-20 °C + 55 °C

-20 °C + 55 °C

Maximum length of rod

4 m

6* (8 mt)

* with 8 m bar