17

F. Maintenance

In order to lensure a uniformly high separation efficiency of the filter unit, it is necessary to carry

out regular (daily or weekly, depending on use) checks and maintenance on the filter elements.

F-1 Pre-Filter Insert

The pre-filter insert is like the after-filter insert equiped with an replaceable pre-filter mat.

Those pre-filter mats can be replaced with a minimum of effort. Just procced as in step C-3

described.

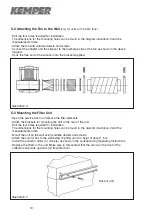

F-2 Collector cell

F-2.1 Cleaning

The collector cell is also cleaned at a suitable place using a high-pressure cleaner or a steam jet

unit. Of course, the collector cell can also be cleaned using a water hose or in a washing trough.

In this case, an aluminium-compatible detergent should be used.

The collector cell should be examined after cleaning. Any torn ionization wires must be replaced

and bent collector plates realigned as they will otherwise cause a short-circuit.

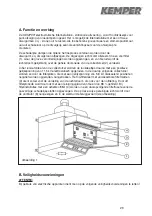

Only when the collector cell and pre-filter insert are completely dry they may be reinserted into the

unit. Make sure in this context that the collector cellis inserted into the housing in the specified

direction (arrow on the front end of the cell).

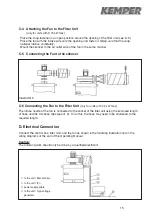

F-2.2 Replacement of Ionization Wires

A broken or torn wire will cause a short-circuit during operation. These breakdowns and any other

short-circuit in the cell are indicated by the high-voltage monitoring system (red indicator lamp).

Broken wires must be replaced as quickly as possible. All pieces of the broken wire must be

removed. If necessary, the cell can be operated for a short period with one wire less, with the

separation efficiency naturally being reduced. The spare part No. of the ionizationwires can be

found in the Spare Parts List of these instructions.

Illustration 7

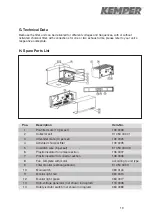

Summary of Contents for 150 0002

Page 2: ......

Page 53: ...51 I 5 Filterüberwachung Filter Monitor Contrôle de saturation ...

Page 54: ......

Page 55: ......

Page 56: ......