6-9

12. Each bit set to ON in the

AIO Panel

should output a logic-high signal

at the corresponding I/O terminal, reading typically about 4 volts

(minimum of 2.2 volts) at a DMM/DVM. Each bit set to OFF in the

AIO Panel

should output a logic-low signal at the corresponding I/O

terminal, reading typically about 0 volts (maximum of 0.8 volts) at a

DMM/DVM. Do one of the following:

Note:

The typical values shown are valid for boards with TTL

compatible outputs. For boards with relay outputs (REL-16, PDISO-8,

and PIO-32) the output will be a relay contact closure. For boards with

open collector outputs (PIO-HV) use a pull up resistor to an appropriate

voltage to detect output state. Refer to the hardware description in this

user’s guide for more details on the output’s electrical specification.

●

If the bit patterns set on the

AIO Panel

do not agree with the

logic levels measured at the I/O terminals, the board is not

functioning properly. Stop here, and determine why.

●

If the bit patterns set on the

AIO Panel

agree with the logic levels

measured at the I/O terminals, then repeat steps 9, 10, and 11 for

remaining output channels.

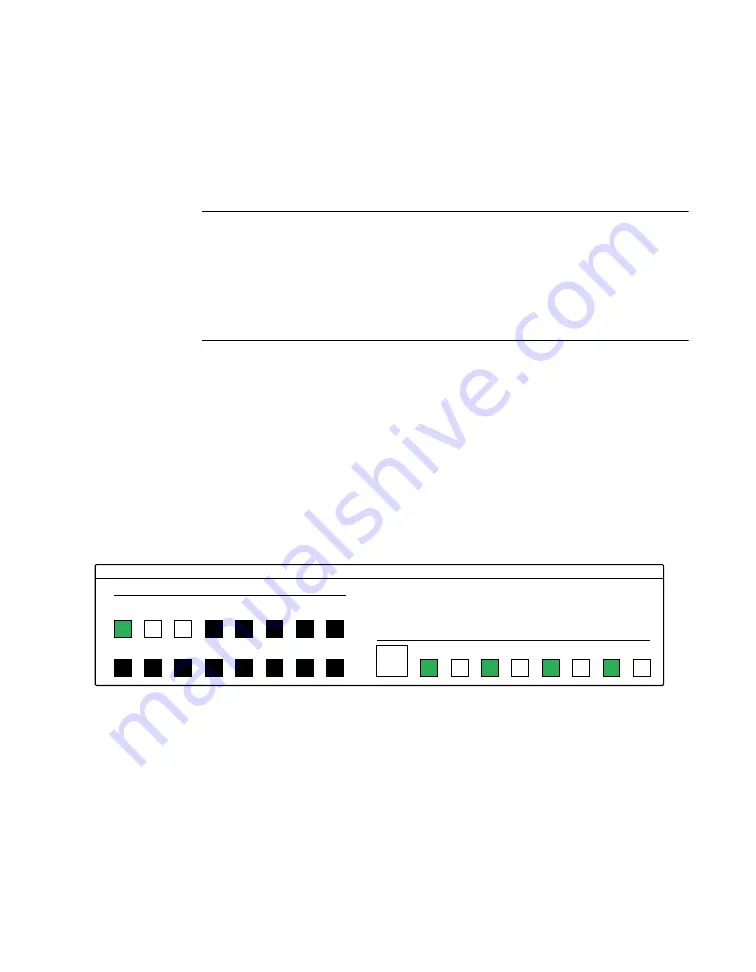

13. In the

Digital Output Panel

under

Channels

, click on the output

channel to test (channel

0

in this example) as shown in Figure 6-8.

Figure 6-8. Configuring channel 0 for output bit pattern B

14. In the

Digital Output Panel

under

Output Bits

, set the bits of

channel

0

for bit pattern B as shown in Figure 6-8.

15. Measure the voltage between signal ground and each bit of the output

port with a DMM or DVM. Make measurements at the STA-50

terminals or the cabled mating connector that is connected to the

selected CONN-3160-D1 50-pin connector.

KEITHLEY

Digital Output Panel

Channels

0

1

2

3

4

5

6

7

7

6

5

4

3

2

1

0

8

9

10

11

12

13

14

15

Output Bits

AA