9.800-199.0 • Kärcher Trailer Manual • Rev. 01/08

OPERA

TOR’S MANU

AL

TRAILER

4

To contact NHTSA, you may either call the Auto

Safety Hotline toll-free at 1-800-424-99 (or 66-

012 in Washington, DC area) or write to NHTSA,

U.S. Department of Transportation, Washington, DC

20590. You can also obtain other information about

motor vehicle safety from the Hotline.

CheCKliST

Before your first trip

❑

Tire Pressure and Tire Condition

❑

Wheel Lugs*

❑

Bearing Lube and Tightness

❑

Burnish Brakes (See page 6)

❑

Brakes/Brake Controllers

❑

Breakaway Battery Charge

❑

Hitch

❑

Safety Chains

❑

12V Running Lights

❑

Distribution and Security

❑

All Jacks “Up” in Travel Position

* Check lug nuts for tightness before initial trip, at

10 miles, 25 miles and 50 miles. Recheck every

months or 000 miles.

Your Kärcher Representative, in all probability,

checked each of these points before you took de-

livery. However, these are key things you should

recheck before taking your trailer on the road for the

first time.

WhaT TO CheCK

aND hOW TO CheCK

Tire Pressure

Proper air pressure for your tires is printed on the

sidewall. Check pressure while tires are cold. Do not

raise or lower pressure to meet load. Pressure other

than recommended pressure will lead to excessive

tire wear or tire failure. Balancing recommended.

Preferred balancing method is to center off of stud

holes, since 1" through 16.5" wheels are not hub

piloted.

Wheels

Check wheels for hole elongation or “out of round”.

This condition can be caused by lug nuts not being

tight or being too tight. Trailer wheels can be dam-

aged by chuck holes or curb jumping. You may not

be aware of the road shock to the wheels without

periodic checks. Replace any wheel that is bent.

Replace any wheel if you see elongation of the bolt

holes.

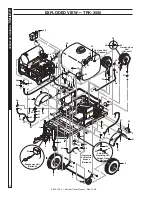

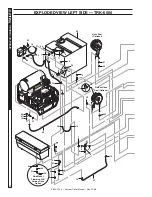

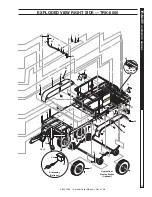

Thank you for purchasing a Kärcher trailer.

This manual is designed to provide information for

you to understand, use and maintain Kärcher trailers

TRK-500 and TRK-6000.

Owner/User responsibility

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this equipment. Warning information should

be emphasized and understood. If the operator is not

fluent in English, the manufacturer’s instructions and

warning shall be read to and discussed with the opera-

tor in the operator’s native language by the purchaser/

owner, making sure that the operator comprehends its

contents.

Owner and/or user must study and maintain for future

reference the manufacturer’s instructions.

This manual should be considered a permanent

part of the equipment and should remain with it

if unit is resold.

When ordering parts, please specify model and

serial number.

MaChiNe SafeTy

WARNING: To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Read the owner’s manual

thoroughly. Failure to follow

instructions could cause mal-

function of the unit and result

in death, serious bodily injury

and/or property damage.

2. The best insurance against an accident is precaution

and knowledge of this equipment.

rePOrTiNg SafeTy

DefeCTS

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or death, you

should immediately inform the National Highway Traffic

Safety Administration (NHTSA) in addition to notifying

Kärcher.

If NHTSA receives similar complaints, it may open an

investigation, and if it finds that a safety defect exists in

a group of vehicles, it may order a recall and remedy

campaign. However, NHTSA cannot become involved

in individual problems between you, your dealer or

Kärcher.

WarNiNg

reaD OPeraTOr’S

MaNUal

ThOrOUghly

PriOr TO USe.

iNTrODUCTiON & iMPOrTaNT SafeTy iNfOrMaTiON