9.800-199.0 • Kärcher Trailer Manual • Rev. 01/08

9

TRAILER

OPERA

TOR’S MANU

AL

BraKeS

Brake adjustment

Brakes should be adjusted (1) after the first 200 miles

of operation after the brake shoes and drums have

“seated”, (2) at 000 mile intervals or () as use and

performance require. The brakes should be adjusted in

the following manner:

1. Jack up trailer and secure on adequate capacity jack

stands. Check that wheel and drum rotate freely.

2. Remove adjusting hole cover from adjusting slot on

bottom of brake backing plate.

. With screwdriver or standard adjusting tool, rotate

the starwheel of the adjuster assembly to expand

the brake shoes. Adjust the brake shoes out until

the pressure of the linings against the drum makes

the wheel very difficult to turn.

Note:

With drop spindle axles, a modified adjusting

tool with about an 80° angle should be used.

4. Then rotate starwheel in opposite direction until

wheel turns freely with slight lining drag.

5. Replace the adjusting hole cover and lower wheel

to ground.

6. Repeat above procedure on all brakes.

CAUTION: Never crawl under your trailer

unless it is resting on properly placed jack

stands.

Do not lift or place supports on any part of the suspen-

sion system.

Brake Cleaning & inspection

Your trailer brakes must be inspected and serviced at

yearly intervals or more often as use and performance

require. Magnets and shoes must be changed when they

become worn or scored thereby preventing adequate

vehicle braking.

Clean the backing plate, magnet arm, magnet and brake

shoes. Make certain that all the parts removed are re-

placed in the same brake and drum assembly. Inspect

the magnet arm for any loose or worn parts. Check shoe

return springs, hold down springs and adjuster springs

for stretch or deformation and replace if required.

CAUTION: Asbestos Dust Hazard. Since

some brake shoe friction materials con-

tain asbestos, certain precautions need

to be taken when servicing brakes:

1. Avoid creating or breathing dust.

2. Avoid machining, filing or grinding the brake lin-

ings.

. Do not use compressed air or dry brushing for clean-

ing. (Dust can be removed with a damp brush).

Trailer STOrage

Preparation

If your trailer is to be stored for an extended period of

time or over the winter, it is important that the trailer

be prepared properly.

1. Remove the emergency breakaway battery and

store inside, out of the weather. Charge the bat-

tery at least every 90 days.

2. Jack up the trailer and place jack stands under

trailer frame so that the weight will be off the tires.

Never jack up or place jack stands on the axle

tube or on the equalizers.

. Lubricate mechanical moving parts that are exposed

to weather, such as hitch and suspension parts.

Note:

On oil lubricated hubs the upper part of the roller

bearings are not immersed in oil and are subject to po-

tential corrosion. For maximum bearing life it is recom-

mended that you revolve your wheels periodically (every

2- weeks) during periods of prolonged storage.

after Prolonged Storage — inspection

Procedures

Before removing trailer from jack stands:

1. Remove all wheels and hubs or brake drums.

Note which spindle and brake that the drum was

removed from so that it can be reinstalled in the

same location.

2. Inspect suspension for wear.

. Check tightness of hanger bolt, shackle bolt and

U-bolt nuts per recommended torque values.

4. Check brake linings, brake drums and armature

faces for excessive wear or scoring.

5. Check brake magnets with an ohmmeter. The

magnets should check .2 ohms. If shorted or

worn excessively, replace.

6. Lubricate all brake moving parts using a high

temperature brake lubricant. (LUBRIPLATE or

equivalent).

CAUTION: Do not get grease or oil on brake lin-

ings or magnet face.

7. Remove any rust from braking surface and arma-

ture surface of drums with fine emery paper or

crocus cloth. Protect bearings from contamina-

tion while so doing.

8. Inspect oil or grease seals for wear or nicks.

Replace if necessary.

9. Lubricate hub bearings. Refer to procedure in

manual.

10. Reinstall hubs and adjust bearings per manual

instructions.

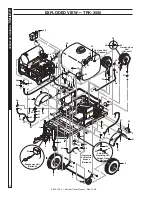

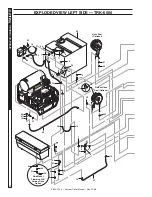

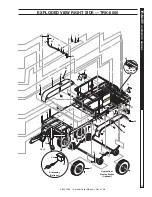

COMPONeNT iDeNTifiCaTiON