9.800-199.0 • Kärcher Trailer Manual • Rev. 01/08

5

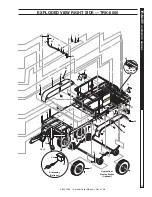

TRAILER

OPERA

TOR’S MANU

AL

Wheel lugs

Wheel lug nuts must be tightened with a torque wrench.

Refer to the chart below for proper torque.

1. Start all bolts or nuts by hand to

prevent cross threading.

2. Tighten bolts or nuts following

sequence at right.

. The tightening of the fasten-

ers should be done in stages.

Following the recommended

sequence, tighten fasteners per wheel torque chart

below.

4. Wheel nuts/bolts should be torqued before first road

use and after each wheel removal. Check and re-

torque after the first 10 miles, 25 miles and again at

50 miles. Check periodically thereafter.

Wheel Torque requirements

Ball Coupler hitches

Coupler assembly includes a latch lever and latch lever

safety pin or hitch pin. Be sure the latch lever is locked

and the pin properly secured before moving your trailer.

The pin can be engaged fully only if ball is properly

seated in the coupler.

hitch Balls

These come in a variety of diameters and capacities.

The GVWR (General Vehicle Weight Rating) capacity

is always stamped on the ball. Use a 2" ball.

always

be

sure the hitch ball at least matches the GVWR of your

trailer.

always

be sure the diameter of the hitch ball

matches the coupler diameter.

Never

attempt to tow

your trailer with improper size ball.

always

keep ball

greased to avoid excessive wear. Replace worn hitch

ball or locking dogs promptly.

Tires

Before mounting tires onto wheels make certain that

the rim size and contour is approved for the tire as

shown in the Tire and Rim Association Yearbook or the

tire manufacturer’s catalog. Also make sure the tire will

carry the rated load. If the load is not equal on all tires

due to trailer weight distribution, use the tire rated for the

heaviest wheel position.

Note:

The capacity rating molded into the sidewall

of the tire is not always the proper rating for the

tire if used in a trailer application. Use the following

guideline:

1. LT and ST tires: use the capacity rating molded

into the tire.

2. Passenger Car Tires: Use the capacity rating

molded into the tire sidewall divided by 1.10.

Use tire mounting procedures as outlined by the

Rubber Manufacturer’s Association or the tire manu-

facturers.

Tire inflation pressure is the most important factor in

tire life. Inflation pressure should be as recommended

by the manufacturer for the load. Pressure should

be checked cold before operation. Do not bleed air

from tires when they are hot. Check inflation pres-

sure weekly during use to insure the maximum tire

life and tread wear. The following tire wear diagnostic

chart will help you pinpoint the causes and solutions

of tire wear problems.

Note:

Tire wear should be checked frequently

because once a wear pattern becomes firmly es-

tablished in a tire it is difficult to stop, even if the

underlying cause is corrected.

Wheel

Size

TOrqUe SeqUeNCe

1st Stage

2nd Stage

3rd Stage

14"

20 - 25

50 - 60

90 - 120

Wear PaTTerN

CaUSe

aCTiON

ACTION

Center

Wear

Over

Inflation

Adjust pressure

to particular

load per tire

catalog.

edge

Wear

Under

Inflation

Adjust pressure

to particular

load per tire

catalog.

Side Wear

Loss of

camber or

overloading

Make sure load

doesn't exceed

axle rating.

Align at align-

ment shop.

Toe Wear

Incorrect

toe-in

Align at align-

ment shop.

Cupping

Out of

balance

Check bearing

adjustment and

balance tires.

flat

Spots

Wheel

lockup & tire

skidding

Avoid sudden

stops when

possible and

adjust brakes.

WhaT TO CheCK aND hOW TO CheCK

1

2

3

4

5