7

Service and Repair Manual

Model 1400KV/1400BV

DISMANTLING

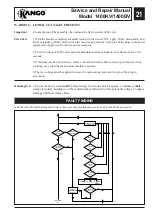

Fig. 1

Fig. 2

Fig. 3

Important!

Before carrying out any repairs, the hammer should be checked for electrical safety and for mechanical

performance. For electrical safety the hammer should be placed on a non-conductive surface which is

either of a wooden construction (with the mains supply disconnected) which contains no metal parts or a

bench which is insulated by a rubber mat. The hammer should then be checked by high voltage flash

testing. On completion of dismantling procedure all electrical components should then be checked for

electrical safety. The hammer should

ONLY

be checked for hammer performance if the unit passes the

electrical safety test.

Removing the

tool locking

mechanism

(1400, 1400B)

1.

Using a hammer and suitable drift, remove the

latch bar (4).

2.

Remove and retain the latch end retainer (7),

spring (6) and cover (5).

Removing

the nosepiece

(1400, 1400B)

1.

Remove the six Allen retaining screws (35) from

the nose piece (8).

2.

Remove the nosepiece assembly (8).

3.

Remove the six allen screws (35) from the anvil

housing (14) and remove anvil housing (14).

4.

Remove and discard O-rings (3) & (11).

Removing the

front handle

mechanism

(1400, 1400B)

1.

Remove the circlip (1), knob (28), and retaining

screw (27) together with the associated washer

(29).

2.

Remove the front handle (30), nose cap (2) and

strap casting (26).

Warning: Hold strap casting (26) whilst

removing nose cap (2).

4

8

5 6 7

1

2

28

26

27

30

3

35 8 11

14

34

29

35

Summary of Contents for 1400 Series

Page 1: ......