The valve opens to protect the machine if the maximum permissible working pressure is ex‐

ceeded.

➤ Never operate the machine without a correctly functioning pressure relief valve.

➤ Do not adjust the pressure relief valve.

Precondition Machine running under LOAD.

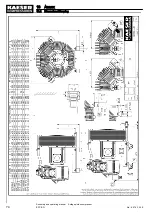

Fig. 27 Checking the pressure relief valves on the cylinder head, collecting pipe and air cooler

1

Pressure relief valve

2

Knurled knob

A

Cylinder head relief valve

B

Pressure relief valve in the collecting pipe

C

Air cooler relief valve

WARNING

The pressure relief valve may blow off at any time!

Excessive noise is caused when the pressure relief valve blows off!

There is danger of injury from bursting components and compressed air!

➤ Wear ear and eye protection.

1. Turn the knurled knob on the pressure relief valve anticlockwise until air blows off.

2. Then turn the knurled knob back to its original position.

Pressure relief valve does not blow off?

➤ Have the defective relief valve replaced by KAESER Service.

10.12 Venting the machine (de-pressurising)

Even when switched off, the machine is still under pressure from the air main to the user's check

valve.

The machine must be fully disconnected from compressed air network and de-pressurised be‐

fore commencing any maintenance or service work requiring an opening of the pressure system.

If no shut-off valve between machine and compressed air network is provided by the user, the

entire air network must be vented.

Precondition The supply isolating device is switched off,

the device is locked off,

a check has been made that no voltage is present.

Machine is cooled down.

10 Maintenance

10.12 Venting the machine (de-pressurising)

No.: 9_5753_04 E

Assembly and operating manual 2-stage piston compressor

EPC-2-G

59