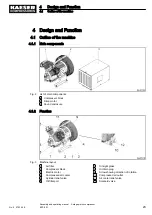

Fig. 14 Oil level monitor connections

1

Compressor block

2

Oil level monitor

Oil level monitoring and direct online starting

Oil level monitoring and star-delta starting

Machines with direct online starting and an

under-voltage cut-out on the pressure switch

require additional control and connection

components.

1. Electrical connections to be made by the

user.

2. The machine is switched off by the pressure

switch.

Machines with star-delta starting require ad‐

ditional control and connection parts and an

external control unit. The oil level monitor

must be linked with the external controller so

that the machine is shut down if oil falls below

the set minimum level.

1. The user is to make the connection to the

power supply or the connection to an external

control unit.

2. The machine is switched off by the external

controller.

6.7.1.1 Float switch

The float switch has been set at the factory as follows:

■ The machine shuts down when the oil falls to its minimum permissible level.

■ The tip of the red arrow is visible for 2 mm.

➤ Check the setting and adjust, if required.

6.7.1.2 Adjusting the setting

Adjust the switching point by moving the sensing contact slightly along an arrow.

You may fine-adjust the switching point to the length of the arrow.

■ Moving towards the arrow head lowers the oil level point at which the sensor triggers.

■ Moving away from the arrow head raises the oil level point at which the sensor triggers.

6

Installation

6.7

Options

36

Assembly and operating manual 2-stage piston compressor

EPC-2-G

No.: 9_5753_04 E