26

| Kaden Installation Manual

DO NOT DEFORM PIPE

WHILE CUTTING

Be extra careful not to damage, dent, or deform the

pipe while cutting. This will drastically reduce the heating

efficiency of the unit.

Step 2: Remove burrs

Burrs can affect the tight seal of refrigerant piping connection.

They must be completely removed.

1. Hold the pipe at a downward angle to prevent burrs from

falling into the pipe.

2. Using a reamer or deburring tool, remove all burrs from the

cut section of the pipe.

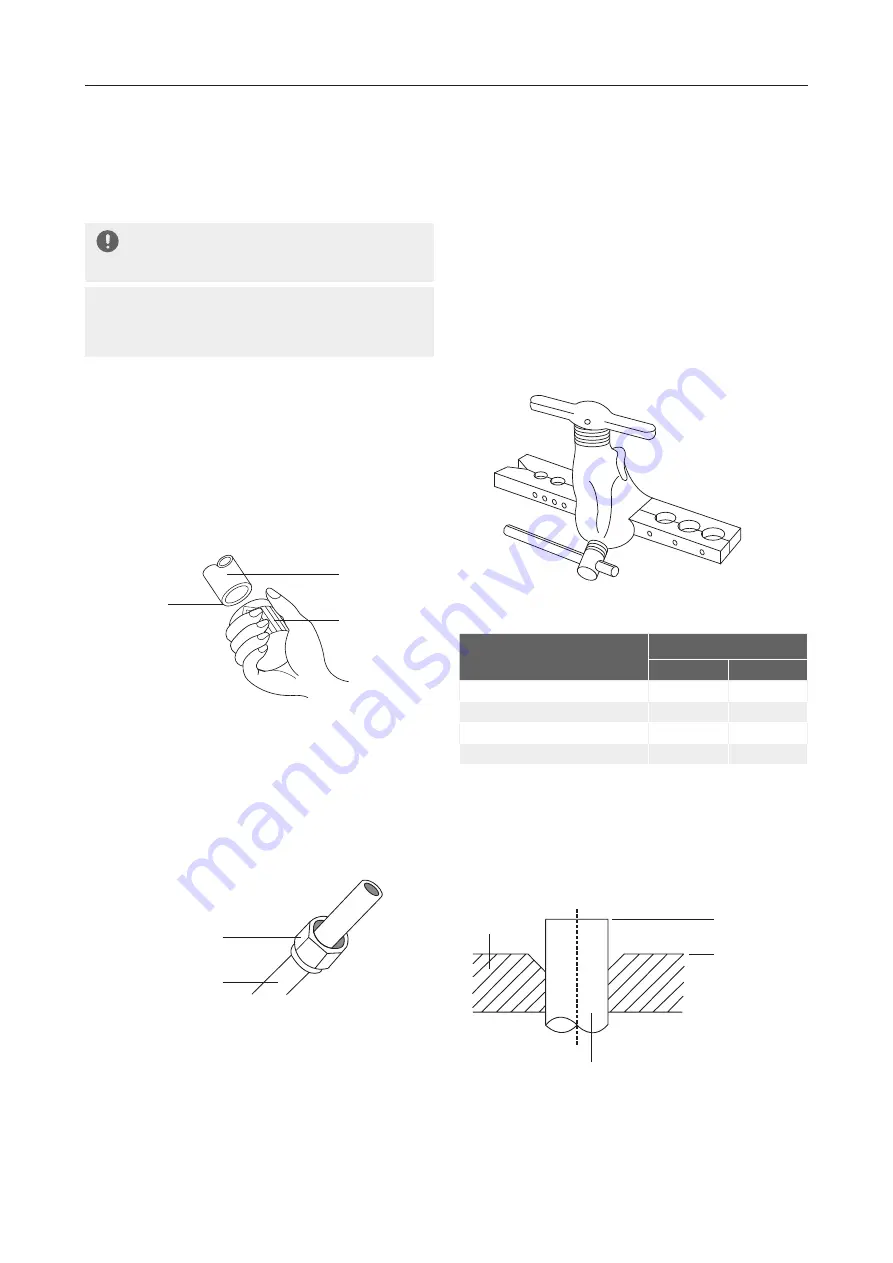

Step 3: Flare pipe ends

Proper flaring is essential to achieve a tight seal.

1. After removing burrs from cut pipe, seal the ends with PVC

tape to prevent foreign materials from entering the pipe.

2. Sheath the pipe with insulating material.

3. Place flare nuts on both ends of pipe. Make sure they are

facing in the right direction, because you can’t put them on

or change their direction after flaring.

4. Remove PVC tape from ends of pipe when ready to

perform flaring work.

5. Clamp flare form on the end of the pipe. The end of the

pipe must extend beyond the edge of the flare form in

accordance with the dimensions shown in the table below.

Flare connection size (A)

A (mm)

Min.

Max.

Ø 6.35

0.7

1.3

Ø 9.52

1.0

1.6

Ø 12.70

1.0

1.8

Ø 15.88

2.0

2.2

6. Place flaring tool onto the form.

7. Turn the handle of the flaring tool clockwise until the pipe is

fully flared.

8. Remove the flaring tool and flare form, then inspect the end

of the pipe for cracks and even flaring.

A

Flare form

Pipe

Pipe

Deburrer

Point down

Copper pipe

Flare nut

Summary of Contents for KSI Series

Page 44: ...kadenair com au...