6720813046-66.1N

2.

1.

Cerapur GC9000iW

6720813052 (2016/10)

1.

1.

1.

2.

6720813046-65.1N

12.5 Visual inspection for general signs of corrosion

12.6 Clean and fill condensate siphon

12.4 Check the burner and non-return valve in the mixer

gen

6720813046-79.1N

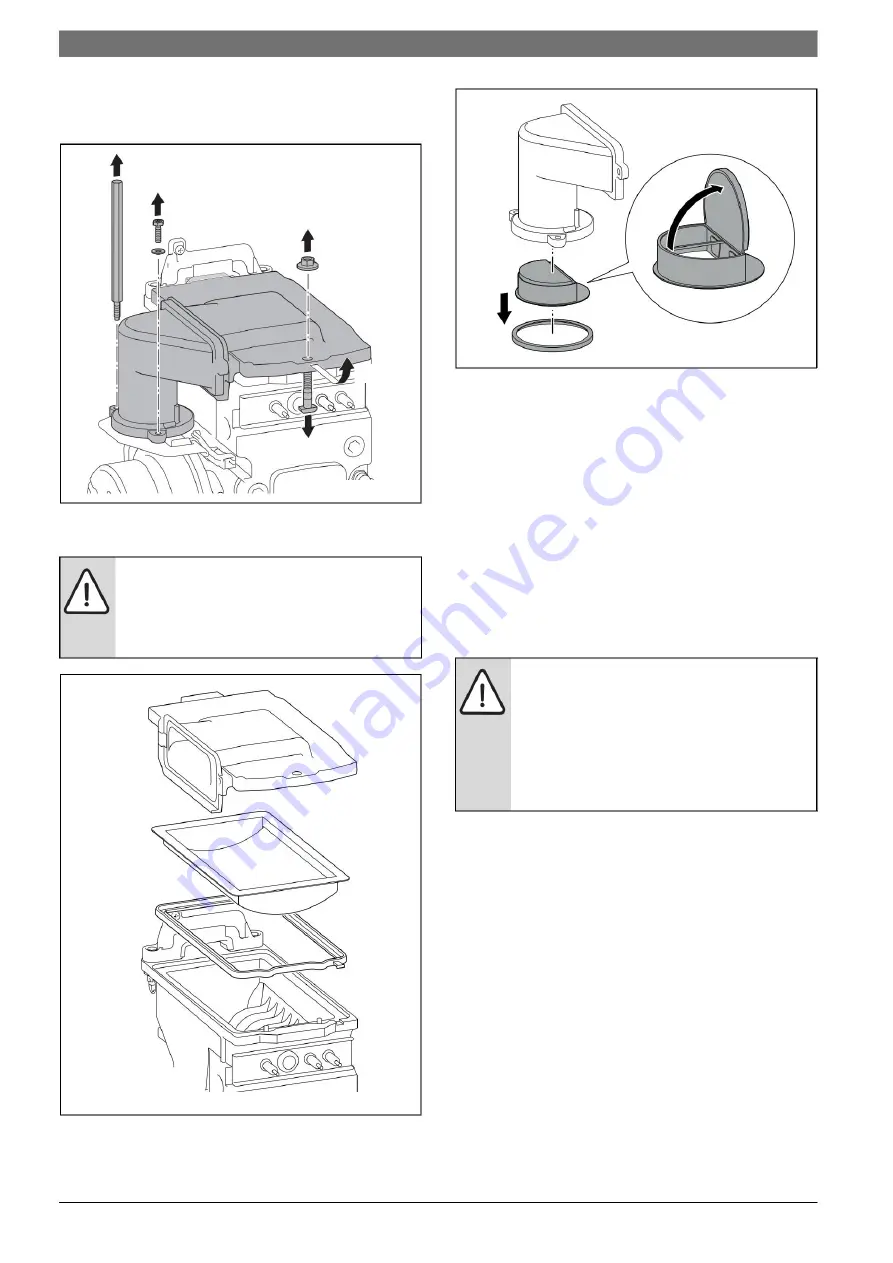

ÿ Remove burner and clean parts.

fen.

Fig. 41 Remove burner cap

If the condensate siphon is not filled with water, escaping

flue gas can endanger people's lives. ÿ Before reinserting,

fill the condensate siphon with water. ÿ Check the seal

for gas tightness after installation

Fig. 43 Non-return valve in the mixing device

check.

ÿ Replace any corroded pipes. ÿ Also visually

inspect the burner, heating block, siphon, automatic air vent and all

couplings in the device.

Fig. 42 Remove the burner

32 | Inspection and Maintenance

ÿ All gas and water-carrying pipes for signs of corrosion

ÿ Unlock condensate siphon [1]. ÿ

Push the condensate siphon forwards. ÿ Take

out the condensate siphon downwards. ÿ Check

the opening to the heating block for continuity. ÿ

Remove and clean the siphon cover. ÿ Check the

condensate hose and clean if necessary.

ÿ Install non-return valve. ÿ Install

burner. ÿ Install burner cap with

mixing device. ÿ Check the gas/air ratio.

assemble follow.

ÿ Measure the CO/CO2 content (ÿ page 19).

check device ÿ

Remove burner cap with mixing device.

Final work:

CAUTION: Damage to the new seal. ÿ First

mount the new seal on the burner. ÿ Burner with new

gasket in reverse rows

ÿ Remove the check valve. ÿ

Check the non-return valve for dirt and cracks.

WARNING: Exhaust Poisoning .

Machine Translated by Google

Summary of Contents for Cerapur 9000i

Page 41: ...6720813052 2016 10 Cerapur GC9000iW 41 notes Machine Translated by Google...

Page 42: ...6720813052 2016 10 Cerapur GC9000iW 42 notes Machine Translated by Google...

Page 43: ...Cerapur GC9000iW 6720813052 2016 10 43 notes Machine Translated by Google...

Page 45: ...Machine Translated by Google...