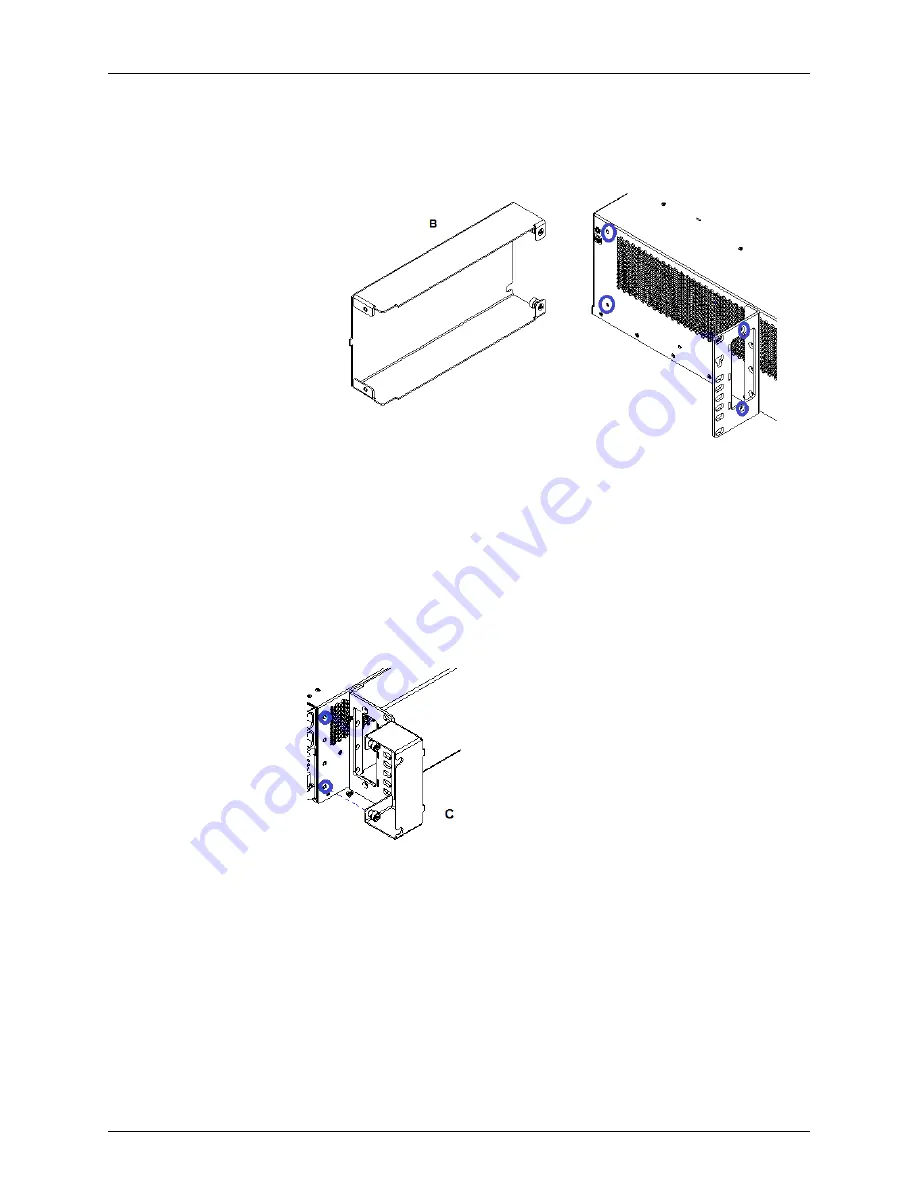

a. Place the air deflector behind the 23-inch mounting bracket.

b. Insert the metal tab into the slot of the 23-inch mounting bracket.

c. Align the bracket drill holes with the mounting bracket screw inserts. Fasten the

bracket to the mounting bracket using the two M3.5 screws.

d. Align the captive screws on the rear of the bracket to the chassis screw inserts.

Fasten the captive screws.

e. Ensure all surfaces are flush.

3.

Install the right front air intake.

a. Place the air intake in front of the 23-inch mounting bracket.

b. Insert the metal tab into the slot of the 23-inch mounting bracket.

c. Align the captive screws on the bracket to the chassis screw inserts. Fasten the

captive screws.

d. Ensure all surfaces are flush.

4.

Install the left front cover.

Copyright © 2019, Juniper Networks, Inc.

82

BTI7800 Series Hardware Overview and Installation Guide

Summary of Contents for BT8A78CH1

Page 20: ...Copyright 2019 Juniper Networks Inc xx BTI7800 Series Hardware Overview and Installation Guide...

Page 68: ...Copyright 2019 Juniper Networks Inc 68 BTI7800 Series Hardware Overview and Installation Guide...

Page 74: ...Copyright 2019 Juniper Networks Inc 74 BTI7800 Series Hardware Overview and Installation Guide...

Page 99: ...99 Copyright 2019 Juniper Networks Inc Chapter 4 Installing the BTI7800 Series Chassis...