– 26 –

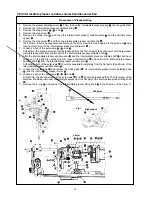

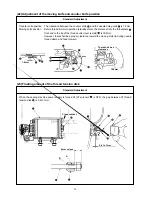

(15) Adjustment of hook oil amount

(16) Shuttle connection / disconnection and oil wick piping

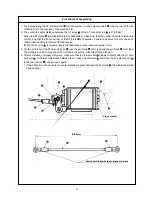

1. Loosen the 5 setscrews

.

2. Remove the setscrew

and pull the oil tank

in the direction of the arrow A.

3. Pull Part B upwards of the two lubrication pipes

and

. Take them out of the oil tank

.

4. Loosen 2 setscrews

of the clamp

in the waste oil pipe

, and remove the clamp

and the setscrew

.

5. Loosen the setscrew

and take out the driver

.

6. Loosen the setscrew

.

7. Remove the setscrew

and pull out the shuttle race adjust shaft

.

8. Pull the shuttle

in the direction of the arrow C and take it out.

Standard Adjustment

Procedures of disassembling

Top surface

of the bed

Rear side of

the bed

A

B

C