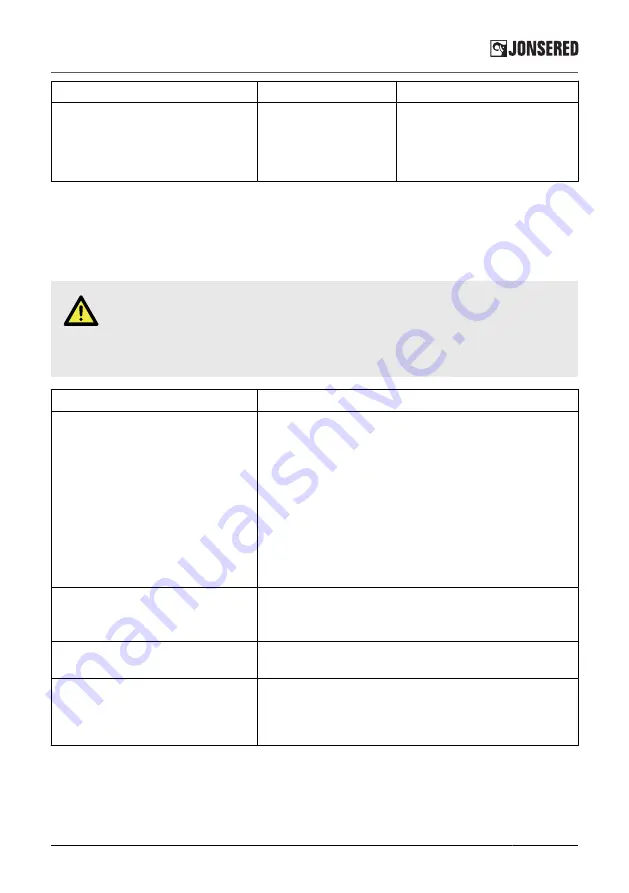

Fault

Probable cause

Action

Leak on hydraulic system: leaking

coupling, hose or line.

Danger! Keep well away from

an oil leak.

1. Press a Stop button.

2. Disengage the PTO.

3. Contact a HIAB service

workshop.

12.9.2. Faults on the CE device

Faults in the crane must be rectified immediately.

Every CE device is tested before delivery. If you encounter problems, check the troubleshooting

chart below before contacting Hiab service workshop.

DANGER

• Only correct yourself the faults that according to the table you may rectify.

• Follow the instructions exactly!

• All other faults must be corrected by personnel in a HIAB service workshop!

Fault

Action

The crane cannot be operated (oil

flows in unloaded circuit). The

warning triangle possibly double-

blinks.

1. Check that the stop button has been released.

2. Check that there are no other hydraulic/mechanical

faults – PTO can be activated, etc.

3. Check that the wire from the dump valve to the

electric unit is undamaged

4. Disconnect the Hirschmann connector from the

dump valve and measure that there is a voltage of

24 VDC between terminals 1 and 2

5. If the dump valve receives 24 VDC but oil still flows

in unloaded circuit, the dump valves must be

replaced at Hiab service workshop.

The warning triangle in the CE

electric unit double-blinks

regardless of the crane’s load.

1. Check that the stop button has been released.

2. Check that all the cables are undamaged

3. Go to a Hiab service workshop

The warning triangle does not

blink/ stay lit at maximum load.

Go to a Hiab service workshop

The truck’s engine stops when the

hydraulic PTO is switched on,

when the crane’s CE system

controls the engine stopper.

1. Check that the stop button has been released.

2. Check the conections

3. Go to a Hiab service workshop

Maintenance and Service

Jonsered 1188S CE

89