INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

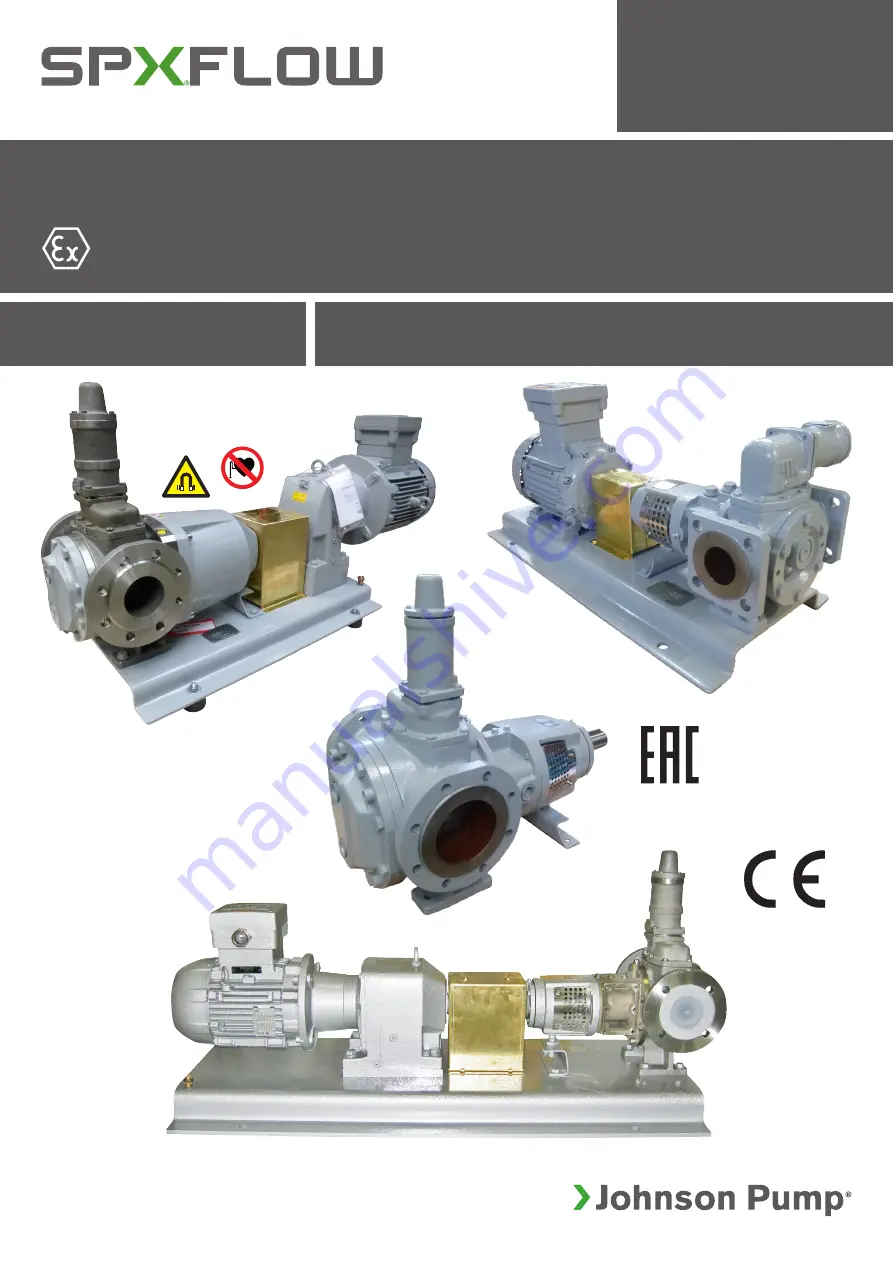

TopGear GS, GP, GM, H, MAG, SRT

EXPLOSION PROTECTION ACCORDING TO 2014/34/EU (ATEX 114)

A.0500.601 – Atex IM-TG G/ H/ MAG/ SRT/ 08.00

EN (01/2021)