437642-UIM-C-0210

Johnson Controls Unitary Products

17

Horizontal portions of the venting system shall be supported to prevent

sagging using hangers or perforated straps and must slope upwards

not less than 1/4” per foot (21 mm/m) from the furnace to the vent termi-

nal.

It is recommended that you follow the venting safety procedure below.

This procedure is designed to detect an inadequate ventilation system

that can cause the appliances in the area to operate improperly causing

unsafe levels of Carbon Monoxide or an unsafe condition to occur.

SECTION VII: START-UP AND

ADJUSTMENTS

The initial start-up of the furnace requires the following additional

procedures:

When the gas supply is initially connected to the furnace, the gas piping

may be full of air. In order to purge this air, it is recommended that the

ground union be loosened until the odor of gas is detected. When gas is

detected, immediately retighten the union and check for leaks. Allow

five minutes for any gas to dissipate before continuing with the start-up

procedure. Be sure proper ventilation is available to dilute and carry

away any vented gas.

NOx SCREEN REMOVAL (Lo-NOx Models Only)

If the furnace is equipped with NOx screens and is to be used with LP

(propane) gas, the screens must be removed prior to start-up.

1.

Make sure that the electrical power to the unit is turned off and that

the gas supply is turned off at the shut-off valve.

2.

Remove the blower compartment and burner compartment access

doors.

3.

Disconnect the gas supply piping at the union to permit removal of

the entire burner and gas control assembly from the vestibule

panel. Use the wrench boss on the gas valve when removing or

installing the piping.

4.

Unplug the igniter from the wire harness. Disconnect the flame

sensor wires located on top of the air shield. Unplug the gas valve

from the wiring harness.

5.

Remove the screws holding the burner assembly to the vestibule

panel.

6.

Remove the burner assembly. It should be possible to swing the

burner assembly out of the way without disconnecting the remain-

ing wires.

7.

With the burner assembly out of the way, simply slide the NOx

screens out of the heat exchanger tubes and discard the screens.

8.

Replace all components in reverse order. Reconnect all wiring.

GAS PIPING LEAK CHECK

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system being placed into operation could result in carbon-

monxide poisoning or death.

The following steps shall be followed for each appliance connected to the venting system being placed into operation, while all other appliances

connected to the venting system are not in operation:

1. Inspect the venting system for proper size and horizontal pitch. Determine that there is no blockage, restriction, leakage, corrosion or other

deficiencies, which could cause an unsafe condition

2. Close all building doors and windows.

3. Turn on clothes dryers and TURN ON any exhaust fans, such as range hoods and bathroom exhausts, so they shall operate at maximum

speed. Open the fireplace dampers. Do not operate a summer exhaust fan.

4. Follow the lighting instructions. Place the appliance being inspected in operation. Adjust thermostat so the appliance shall operate contin-

uously.

5. Test each appliance (such as a water heater) equipped with a draft hood for spillage (down-draft or no draft) at the draft hood relief opening

after 5 minutes of main burner operation. Appliances that do not have draft hoods need to be checked at the vent pipe as close to the

appliance as possible. Use a combustion analyzer to check the CO

2

and CO levels of each appliance. Use a draft gauge to check for a

downdraft or inadequate draft condition.

6. After it has been determined that each appliance properly vents when tested as outlined above, return doors, windows, exhaust fans, fire-

place dampers and any other gas burning appliance to their normal condition.

7. If improper venting is observed during any of the above tests, a problem exists with either the venting system or the appliance does not

have enough combustion air (Supply Air from outside) to complete combustion. This condition must be corrected before the appliance can

function safely.

NOTE:

An unsafe condition exists when the CO reading exceeds 40 ppm and the draft reading is not in excess of - 0.1” w.c. (-25 kPa) with all

of the appliance(s) operating at the same time.

8. Any corrections to the venting system and / or to the supply (outside) air system must be in accordance with the National Fuel Gas Code

Z223.1 or CAN/CGA B149.1 Natural Gas and Propane Installation Code (latest editions). If the vent system must be resized, follow the

appropriate tables in Appendix G of the above codes or for this appliance.

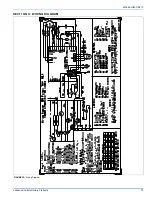

All electrical connections made in the field and in the factory should

be checked for proper tightness.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

Burner ignition may not be satisfactory on first startup due to resid-

ual air in the gas line or until gas manifold pressure is adjusted. The

ignition control will make three attempts to light before locking out.