TEC22x6(H)-4 and TEC22x6H-4+PIR Series L

ON

W

ORKS

® Network Thermostat Controllers with

Dehumidification Capability, Fan Control, and Occupancy Sensing Capability Installation Instructions

3

8.

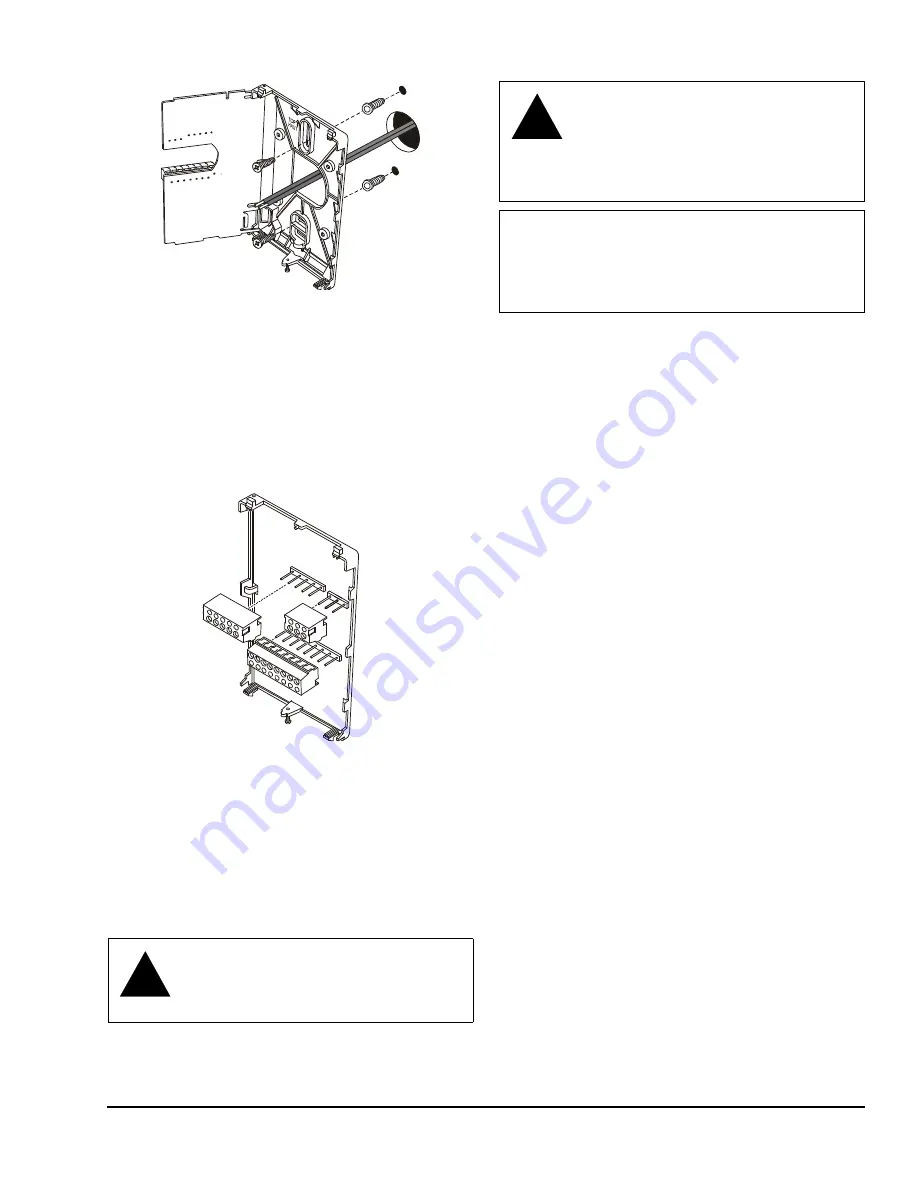

Swing the PCB back to the right and carefully snap

it into the locking tabs on the thermostat mounting

base.

9.

Remove the screw terminal blocks that are

attached to a disposable adhesive. Figure 4

illustrates the locations of the screw terminal

blocks on the thermostat controller.

Wiring

When an existing thermostat is replaced, remove and

label the wires to identify the terminal functions. When

a TEC22x6(H)-4 or TEC22x6H-4+PIR Series

Thermostat is replaced, simply remove the old screw

terminal blocks and reinsert them onto the PCB of the

replacement thermostat.

To wire the thermostat:

1.

Strip the ends of each wire 1/4 in. (6 mm) and

connect them to the appropriate screw terminals as

indicated in Table 1, and Figure 6 through

Figure 10.

Note:

For more details on wiring the L

ON

W

ORKS

network, refer to the

L

ON

W

ORKS

Network Layout

Technical Bulletin (LIT-1162150).

2.

Carefully push any excess wire back into the wall.

Note:

Seal the hole in the wall with fireproof

material to prevent drafts from affecting the

ambient temperature readings.

3.

Reinsert the screw terminal blocks onto the PCB.

4.

Reattach the L

ON

W

ORKS

communication wires to

the LON terminal block. See Figure 5.

Note:

If inserting multiple wires into the terminals,

be sure to properly twist wires together prior to

inserting them in the terminal connectors.

5.

Reattach the thermostat cover to the mounting

base (top side first).

6.

Use a Phillips-head screwdriver to reinstall the

security screw on the bottom of the thermostat

cover.

!

CAUTION: Risk of Electric Shock.

Disconnect power supply before making

electrical connections to avoid electric

shock.

Figure 3: Securing the Thermostat

Mounting Base to the Wall

FI

G

:m

tgbs

Figure 4: Removing the Screw Terminal Blocks

F

IG

:t

rm

n

l_

b

lc

k

s

!

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires

may result in permanent damage to the

equipment.

IMPORTANT:

Make all wiring connections in

accordance with local, national, and regional

regulations. Do not exceed the electrical ratings of

the TEC22x6(H)-4 and TEC22x6H-4+PIR Series

Thermostat Controllers.