TEC22x6(H)-4 and TEC22x6H-4+PIR Series L

ON

W

ORKS

® Network Thermostat Controllers with

Dehumidification Capability, Fan Control, and Occupancy Sensing Capability Installation Instructions

2

Note:

Allow for vertical air circulation to the

TEC22x6(H)-4 and TEC22x6H-4+PIR Series

Thermostat Controllers.

To install the thermostat:

1.

Use a Phillips-head screwdriver to remove the

security screw on the bottom of the thermostat

cover.

Note:

Normally, the security screw is packaged

separately in a plastic bag with the thermostat

controller. Skip this step if the screw is not installed

on the bottom of the cover.

2.

Pull the bottom edge of the thermostat cover and

open the thermostat as illustrated in Figure 1.

Note:

PIR models have a wiring connection

between the cover and the Printed Circuit Board

(PCB). This connection allows for proper wiring of

the occupancy sensor. Carefully remove the wiring

connection from the PCB by pulling up on the

connector block.

Do not attempt to remove the

connector block by pulling on the wires

3.

Carefully pull the locking tabs on the right side of

the thermostat mounting base and unlock the PCB.

Open the PCB to the left as illustrated in Figure 2.

4.

Pull approximately 6 in. (152 mm) of wire from the

wall and insert the wire through the hole in the

thermostat mounting base.

5.

Align the thermostat mounting base on the wall and

use the base as a template to mark the two

mounting hole locations.

6.

Position the thermostat mounting base so that the

arrow on the base points upward to indicate the top

of the thermostat.

Note:

If you need to install the thermostat on an

electrical junction box, use 2-1/2 x 4 in.

(63 x 101 mm) square boxes with mud ring covers,

and avoid smaller 1-1/2 x 4 in. (38 x 101 mm) or

3 x 2 in. (76 x 51 mm) square boxes. This

procedure ensures that you have enough space for

cabling and end-of-line devices, if needed.

Note:

For surface-mount applications, use

durable mounting hardware such as Molly bolt

anchors that cannot be easily pulled out of the

mounting surface.

7.

Secure the mounting base to the wall surface using

two mounting screws as illustrated in Figure 3.

Note:

Be careful not to overtighten the mounting

screws.

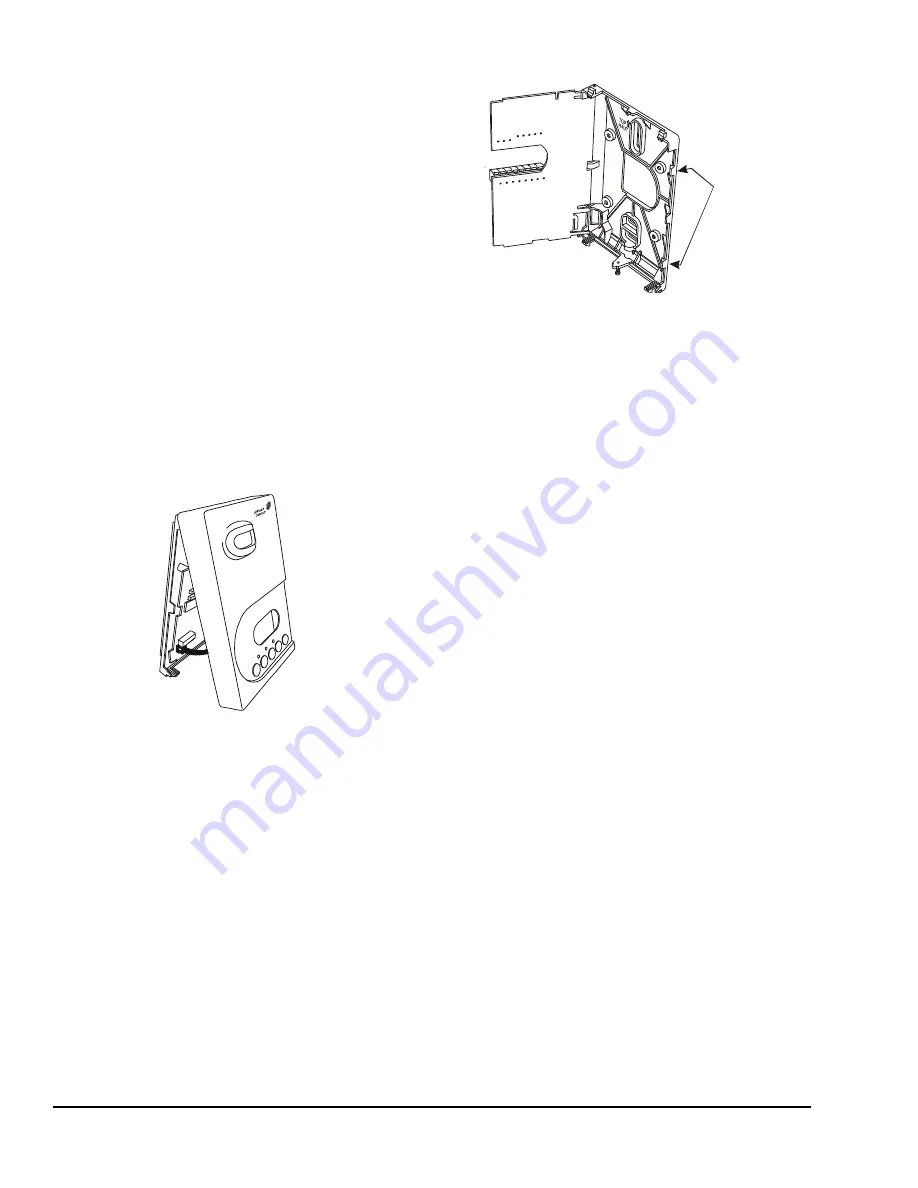

Figure 1: Removing the Thermostat Controller

Cover (TEC22x6H-4+PIR Model Shown)

F

IG

:c

v

r_

rm

v

l

Figure 2: Opening the Thermostat PCB

FIG

:pr

nc

tb

d

PCB

Locking

Tabs