RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM (OCT04)

Page 38

JORDAN

TEMPERATURE REGULATOR VALVE

The Jordan valve is a high volume, tem-

perature-regulating valve that requires

minimal differential across the valve to

ensure adequate flow for cooling.

The Jordan valve must be mounted on a

horizontal line with the flow arrow point-

ing toward the direction of flow. However,

the valve may be mounted at any angle

perpendicular to the horizontal line, in-

cluding inverted, if necessary.

Sensing Bulb, Vertical Mounting -

When the sensing bulb is to be mounted vertically (pointing

down), no special precaution is necessary. If the bulb is to be

mounted vertically, in an inverted position, a special capillary

is needed because the tip of the sensing bulb is higher than

the capillary end.

Sensing Bulb, Horizontal Mounting -

When mounting the

sensing bulb horizontally it must be mounted so that the

word “TOP” which is stamped on the capillary end of the bulb

appears accordingly.

NOTE: No angular mounting of the

sensing bulb is permitted.

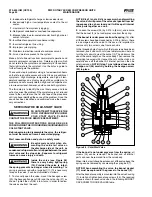

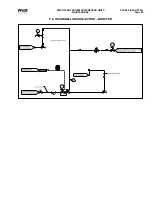

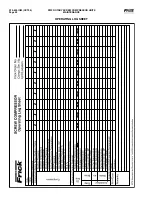

Adjustment -

To in-

crease the oil tem-

perature, increase the

spring tension by turn-

ing the knurled nut at

the base of the spring.

To decrease the oil tem-

perature, decrease the

spring tension by turn-

ing the knurled nut at

the base of the spring

(see Figure 36).

Action -

The valve

should be set as a re-

verse acting valve, how-

ever there are times when the valve may be set as a direct

acting valve. If you experience what seems to be a total

absence of oil cooling you will need to check the action of

the valve.

To check the action you will need to remove the

cap-flange and disc-guide.

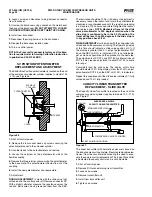

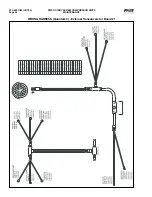

If the hole in the valve plate is to the left and the slot in the

valve disc is on the top this valve is set for

Direct Acting (see

Figure 37)

.

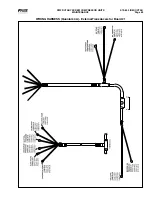

To change the action of the valve to Reverse Act-

ing simply rotate the valve plate and the valve disc 180° so

that the hole on the plate is on the right and the slot on the

disk is at the bottom (see Figure 38).

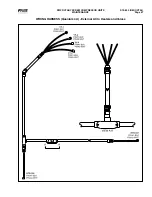

LOOSEN

DISC-PIN

LOCKING

NUT

DIRECT

ACTING

Figure 36

Figure 37

Figure 39

•

Loosen the disc-pin locking nut and allow at least 10 min-

utes for the valve to react (see Figure 39).

•

Rotate the disc-pin so that when the valve-plate is installed

the bottom of the pin is between the middle and the bottom

of the slot.

•

Hold the coupling with a wrench and tighten the disc-pin

locking nut.

•

Install the valve-plate and valve-disk for reverse action (see

Figure 38).

•

Install the disk-guide and cap-flange.

•

Increase the spring tension to about 30% by turning the

knurled nut at the base of the spring approximately 20

quarter turns.

ADJUST-

MENT

REVERSE

ACTING

Figure 38

Stroke Adjustment -

After the valve action has been changed

it may be necessary to make a stroke adjustment. This

ensures that the full capacity of the valve is available, if nec-

essary, to keep the oil at the predetermined temperature.

To prepare for a stroke adjustment do the following.

•

Remove the disc-guide, valve-disc, and valve-plate.

•

Expose the sensing bulb in a vertical position to an ambient

temperature of about 80°F.

•

Release all spring tension by loosening the knurled nut.