PAGE 38 of 53

4.

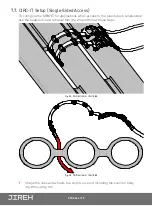

The chain retrieval tool is used to pull the latch through a tight space. The chain

retrieval tool is designed to flip open the latch’s tab, allowing the chain retrieval

tool to hook the latch tab

(Fig. 93) and (Fig. 94)

. The chain retrieval tool can also be

used if available space to retrieve the latch is too small and the tab can not be

opened.

Fig. 93

- Use chain retrieval tool to access latch

Fig. 94

- Use chain retrieval tool to access latch