12

8.0

Lubrication

Do not operate the mill before

lubricating the machine fully. Failure to

comply may cause damage to the machine.

Refer to

section 11.0

and make sure the machine

has been fully lubricated before operating.

9.0

Operating instructions

9.1

Operating controls

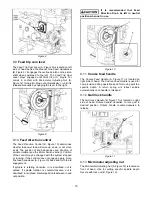

The milling machine is equipped with an automatic

lubrication system. Ensure that reservoir has the

proper amount of lubricant. The system reservoir is

located at rear of machine.

The position of the mill head can be set up to

accommodate the workpiece being machined. The

mill head can be set up for angles to left or right and

for fore and aft angles. The mill head can also be

rotated on its turret. The ram can be moved back

and forth to reach workpiece locations at fore and

aft extremes of worktable travel. Refer to

section

10.0.

9.2

Control panel

The control panel is located on the arm at right side

of machine. See Figure 4 for functions.

Figure 4

A

–

RPM digital readout.

B –

Motor direction switch:

Has two positions:

FWD (forward) and REV (reverse). Setting the

switch to FWD will provide clockwise spindle

rotation. Use FWD for normal, right-hand tooling.

FWD (clockwise) operation occurs only when

gearbox is in low speed position. When gearbox is

in high-speed position, the motor switch must be in

the REV position to provide right-hand or clockwise

rotation. Refer to Table 2 for required switch

positions.

The motor switch controls a three-phase motor. The

motor can be switched from FWD to REV and back

with the motor running, and will reverse direction

when the switch setting is changed. At higher

speeds, this may put strain on the timing belt but

there will be no damage to the motor or gear

mechanism.

C –

Coolant switch

: installed for optional coolant

pump. The wiring must be connected to U2, V2 and

W2 in the terminal strip.

D –

Power lamp

: indicates electrical power is

flowing to machine.

E –

Speed dial

: Sets spindle speed.

F –

Spindle switch

: Engages spindle rotation.

G –

Emergency stop switch

: Shuts down all

controls on machine. Rotate switch clockwise to

disengage and restart machine.

Summary of Contents for JTM-1050EVS2

Page 13: ...13 9 3 Control positions for milling and drilling operations Table 2 ...

Page 23: ...23 13 1 1 JTM 949EVS JTM 1050EVS2 Upper Head Assembly Exploded View ...

Page 26: ...26 13 2 1 JTM 949EVS JTM 1050EVS2 Lower Head Assembly Exploded View ...

Page 30: ...30 13 3 1 JTM 949EVS Base Machine Exploded View ...

Page 33: ...33 13 4 1 JTM 1050EVS2 Base Machine Exploded View ...

Page 36: ...36 13 5 1 JTM 949EVS Table Assembly Exploded View ...

Page 38: ...38 13 6 1 JTM 1050EVS2 Table Assembly Exploded View ...

Page 46: ...46 14 0 Electrical Connections JTM 949EVS JTM 1050EVS2 ...

Page 47: ...47 This page intentionally left blank ...

Page 48: ...48 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...