15

direction as shown on the blade direction

label on saw. (If teeth still point in wrong

direction despite mounting blade properly,

the blade has been turned inside-out. Twist

blade right side-out and reinstall.)

9. Position blade around wheels, making sure

it rests near the flange on both wheels.

10. Tension blade using handle. Do not over-

tension. See

section 9.7,

Blade tension

.

11. Close back cover and secure with knobs.

12. Install red blade guard, and brush assembly.

13. Connect machine to power source.

14. Run machine to verify that blade is tracking

properly. See

section 9.8,

Blade tracking

.

9.7

Blade tension

Disconnect machine from

power source, and use caution when

working with sharp blade.

Blade tension is vital to achieving proper results

from the band saw. For shipping purposes, the

blade may not be at full tension – verify tension

before operating.

Proper blade tension is 1550 to 1760 kg/cm

2

(22000-25000 lb/in

2

) as measured on a blade

tension gauge (not provided).

To set tension without the use of a tension

gauge:

1. Disconnect machine from power source.

2. Install blade between wheels and between

bearings on blade guides.

3. Lightly tension blade to remove any sag by

turning handle (C, Figure 20) slightly

clockwise.

4. Turn tension handle (C, Figure 20) 1-3/4 to

two revolutions clockwise. This is equivalent

to 800 kg (1764 lb) of blade tension.

Do not overtighten blade;

this may cause it to stretch or warp.

5. Close covers, connect to power source, and

run saw for 2 to 3 minutes to allow blade to

seat properly.

6. Disconnect machine from power source.

Open cover and loosen blade until it just

begins to sag.

7. Tighten blade until it straightens between

blade wheels and all sag is eliminated.

8. Tighten blade by turning handle (C, Figure

20) two full revolutions.

TIP:

Slacken blade tension when finished with

operations, to prolong blade life. Make note of

indicator position on tension label (D, Figure 20)

for quickly returning tension to its previous

setting.

9.8

Blade tracking

Tracking the blade requires

that the band saw be operating while the

back cover is removed. This adjustment

should be performed by qualified persons

only.

Blade tracking has been tested at the factory.

Adjustment is rarely required when the blade is

used properly and if the blade is correctly

welded. If a tracking problem occurs, first

inspect blade condition, then adjust tracking as

follows:

1. Raise bow to vertical position and secure by

turning off hydraulic cylinder valve.

2. The blade should be properly tensioned.

Refer to

section 9.7 Blade tension.

3. Open back cover.

While performing the

following steps, keep the blade from rubbing

excessively on wheel flange. Excess rubbing

will damage wheel and/or blade.

4. Start saw and observe blade movement.

Blade should run next to, but not tightly

against, wheel flange.

5. If blade will not track in position, loosen

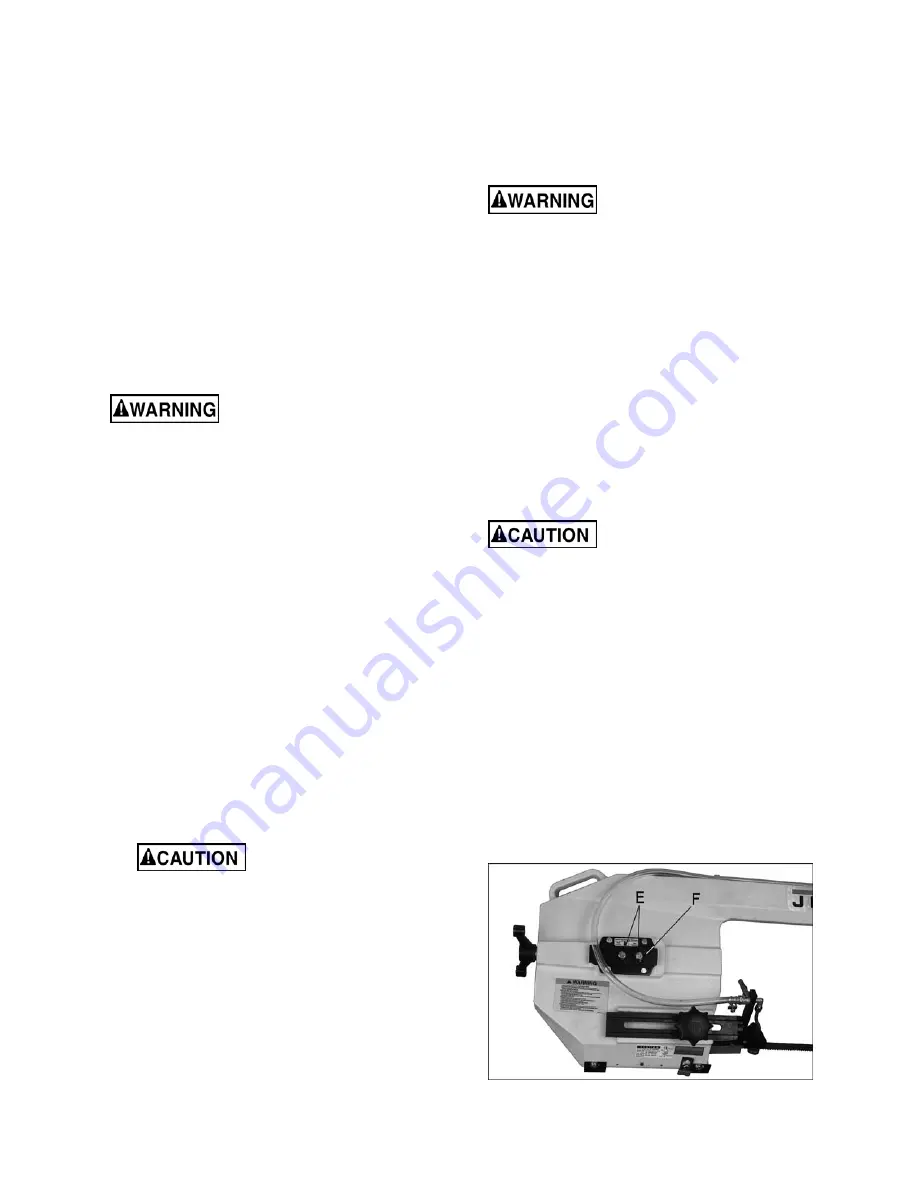

screws (E, Figure 21), but do not remove.

6. Turn set screw (F, Figure 21) counter-

clockwise so that blade starts to move away

from the flange; then immediately turn set

screw in the other direction so that blade

stops, then moves slowly back toward

flange. NOTE: This adjustment is sensitive;

do it gradually and in small increments

allowing blade to respond to the changes.

Figure 21