15

EGH1740 | EGH1760

threading controls.

E. Spindle rotation, forward, stop and reverse.

Fig. 13

9.2 ELECTRICAL CONTROL PANEL

With the exception of the lathe isolator, all electrical

controls are fitted onto the front face of the headstock.

1. WORK LAMP: On/Off switch.

2. POWER INDICATOR LIGHT: When the power is on,

the indicator light glows.

3. COOLANT PUMP: On/Off switch.

4. JOG BUTTON: Push it to move spindle slightly, this

will make spindle speed selection easier.

5. EMERGENCY STOP SWITCH: Press in order to kill

all electric power to lathe.

Fig. 14

9.3 HEADSTOCK SELECTORS

Spindle speed selector

1. The upper two selectors on the headstock are

for spindle speed selection. There are 16 spindle

speeds, as shown on speed chart, divided into four

groups. Each speed is the result of combining the

above two selectors.

2. For instance, if 1000 r.p.m. of spindle speed is to be

chosen, then move left selector to D, and two-speed

motor switch to low range.

H-N-L selector for gearbox

1. Following each feed rate or thread pitch on gearbox

thread and feed chart, there is a prefix of either H or

L.

2. Move H-N-L selector to H or L accordingly for

feeding or threading. If this lever is positioned at

N, the headstock rotation will not be transmitted to

gearbox.

Apron orientation selector

1. This selector may affect the rotation orientation

of the lead screw, feed rod and henceforth the

movement direction of apron.

2. Right-hand arrow (toward tailstock) is used for

cutting right-hand threads. Left-hand arrow (toward

end-guard) is used for cutting left-hand threads.

Fig. 15

9.4 THREADS AND FEEDS

Gearbox, thread and feed selectors

All the thread pitches and feeds directly available from the

gearbox are shown on the data plate fitted on the front

of headstock and the positioning control levers are (G1),

(G2), (G3), and (G4).

B

A

A

C

D

E

1

2

3

4

5

1

2

3

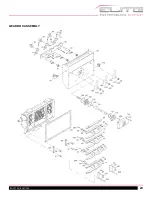

Summary of Contents for 892100

Page 21: ...21 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 22: ...22 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 23: ...23 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 24: ...24 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 28: ...28 1700 Series Lathe GEARBOX ASSEMBLY ...

Page 29: ...29 EGH1740 EGH1760 GEARBOX ASSEMBLY ...

Page 33: ...33 EGH1740 EGH1760 APRON L H ASSEMBLY ...

Page 34: ...34 1700 Series Lathe APRON L H ASSEMBLY ...

Page 39: ...39 EGH1740 EGH1760 4 WAY TOOL POST ...

Page 41: ...41 EGH1740 EGH1760 SADDLES ASSEMBLY ...

Page 42: ...42 1700 Series Lathe SADDLES ASSEMBLY 2 ...

Page 45: ...45 EGH1740 EGH1760 BED AND SHAFTS ASSEMBLY ...

Page 48: ...48 1700 Series Lathe END GEAR ASSEMBLY ...

Page 50: ...50 1700 Series Lathe MAIN MOTOR ASSEMBLY ...

Page 52: ...52 1700 Series Lathe CABINET AND PANEL ASSEMBLY FRONT MOVEABLE CHIP TRAY OPTIONS ...

Page 56: ...56 1700 Series Lathe CONVENTIONAL TAILSTOCK ASSEMBLY ...

Page 58: ...58 1700 Series Lathe STEADY REST ASSEMBLY ...

Page 62: ...62 1700 Series Lathe 892156 5C COLLET CLOSER OPTIONAL ...

Page 64: ...64 1700 Series Lathe 892157 TAPER ATTACHMENT OPTIONAL ...