14

1700 Series Lathe

Fig. 11

Oil can be added or drained via hex drain plug located in

the bottom plate of the apron.

In addition to the one shot lubrication, oiler points are

provided for the saddle cross-slide and cross-slide nut.

Use a standard oil can with light machine oil or way

lubricant.

On the tailstock and tail end of leadscrew, lubrication

points are provided for daily attention from a standard oil

can.

It is recommended that all slideways, the leadscrew and

feed shaft are cleaned daily and then lightly lubricated.

7.5 COMPLETING INSTALLATION

13. Exposed metal surfaces have been coated with a

rust protectant. Remove this using a soft rag and

mild commercial solvent or kerosene. Do not use

paint thinner, gasoline, or lacquer thinner, as these

will damage painted surfaces. Cover all cleaned sur-

faces with a light film of SAE-20W machine oil, such

as Mobil DTE Oil Heavy Medium.

14. Open the end gear cover. Clean all components

of the end gear assembly and coat all gears with

a heavy, non-slinging grease. Close the end gear

cover. (Note: A limit switch prevents the lathe from

operating when the end gear cover is open.)

7.6 BREAK-IN PERIOD

Do not run the lathe above 560 RPM for the first six hours

of operation, to allow gears and bearings to adapt and run

smoothly.

Push during working

A

Fill oil to level

8.0 ELECTRICAL CONNECTIONS

Electrical connections must be made by a qual-

ified electrician in compliance with all relevant

codes. This machine must be properly grounded

while in use to help protect the operator from elec-

trical shock and possible fatal injury.

Confirm that power available at the lathe’s location is the

same rating as the lathe.

IMPORTANT: The lathe must be wired properly

and phased correctly. The spindle should rotate

counterclockwise (as viewed from the tailstock

end) while the feed rod rotates clockwise (as

viewed from the tailstock end). If the phasing

needs correction, disconnect lathe from power

source and switch any two of the three power

leads (not the green ground wire).

Make sure the lathe is properly grounded.

9.0 OPERATION

9.1 LATHE CONTROLS

A. Headstock selector

B. Electrical control

C. Gearbox (threads and feeds)

D. Apron control units, for surfacing, sliding and

Fig. 12

Main Switch

Summary of Contents for 892100

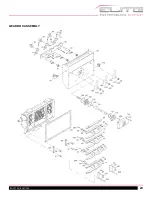

Page 21: ...21 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 22: ...22 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 23: ...23 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 24: ...24 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 28: ...28 1700 Series Lathe GEARBOX ASSEMBLY ...

Page 29: ...29 EGH1740 EGH1760 GEARBOX ASSEMBLY ...

Page 33: ...33 EGH1740 EGH1760 APRON L H ASSEMBLY ...

Page 34: ...34 1700 Series Lathe APRON L H ASSEMBLY ...

Page 39: ...39 EGH1740 EGH1760 4 WAY TOOL POST ...

Page 41: ...41 EGH1740 EGH1760 SADDLES ASSEMBLY ...

Page 42: ...42 1700 Series Lathe SADDLES ASSEMBLY 2 ...

Page 45: ...45 EGH1740 EGH1760 BED AND SHAFTS ASSEMBLY ...

Page 48: ...48 1700 Series Lathe END GEAR ASSEMBLY ...

Page 50: ...50 1700 Series Lathe MAIN MOTOR ASSEMBLY ...

Page 52: ...52 1700 Series Lathe CABINET AND PANEL ASSEMBLY FRONT MOVEABLE CHIP TRAY OPTIONS ...

Page 56: ...56 1700 Series Lathe CONVENTIONAL TAILSTOCK ASSEMBLY ...

Page 58: ...58 1700 Series Lathe STEADY REST ASSEMBLY ...

Page 62: ...62 1700 Series Lathe 892156 5C COLLET CLOSER OPTIONAL ...

Page 64: ...64 1700 Series Lathe 892157 TAPER ATTACHMENT OPTIONAL ...