11

EGH1740 | EGH1760

Read and understand the entire contents of this

manual before attempting set-up or operation.

Failure to comply may cause serious injury.

Confirm that all suspension equipment is properly

rated and in good condition for lifting lathe. Do not

allow anyone beneath or near load while lifting.

8. The lathe can be placed upon the cast iron leveling

pads under each foot hole, and adjusted using the

adjusting bolts with hex nuts. Or, it may be secured

to the floor using bolts placed head-down in the con-

crete, and using shims where needed to level the

machine. Refer to Figure 1 for mounting hole dimen-

sions.

7.1 LEVELING THE LATHE

It is imperative that the lathe be on a level plane; that is,

where headstock and tailstock center points remain aligned

throughout the tailstock travel, with the bed ways absent of

twist and thus parallel to the operational center line.

A lathe which is not properly leveled will be inaccurate, pro-

ducing tapered cuts. Also, the center point of the tailstock

will vary as it is positioned along the bed, thus requiring

constant readjustment.

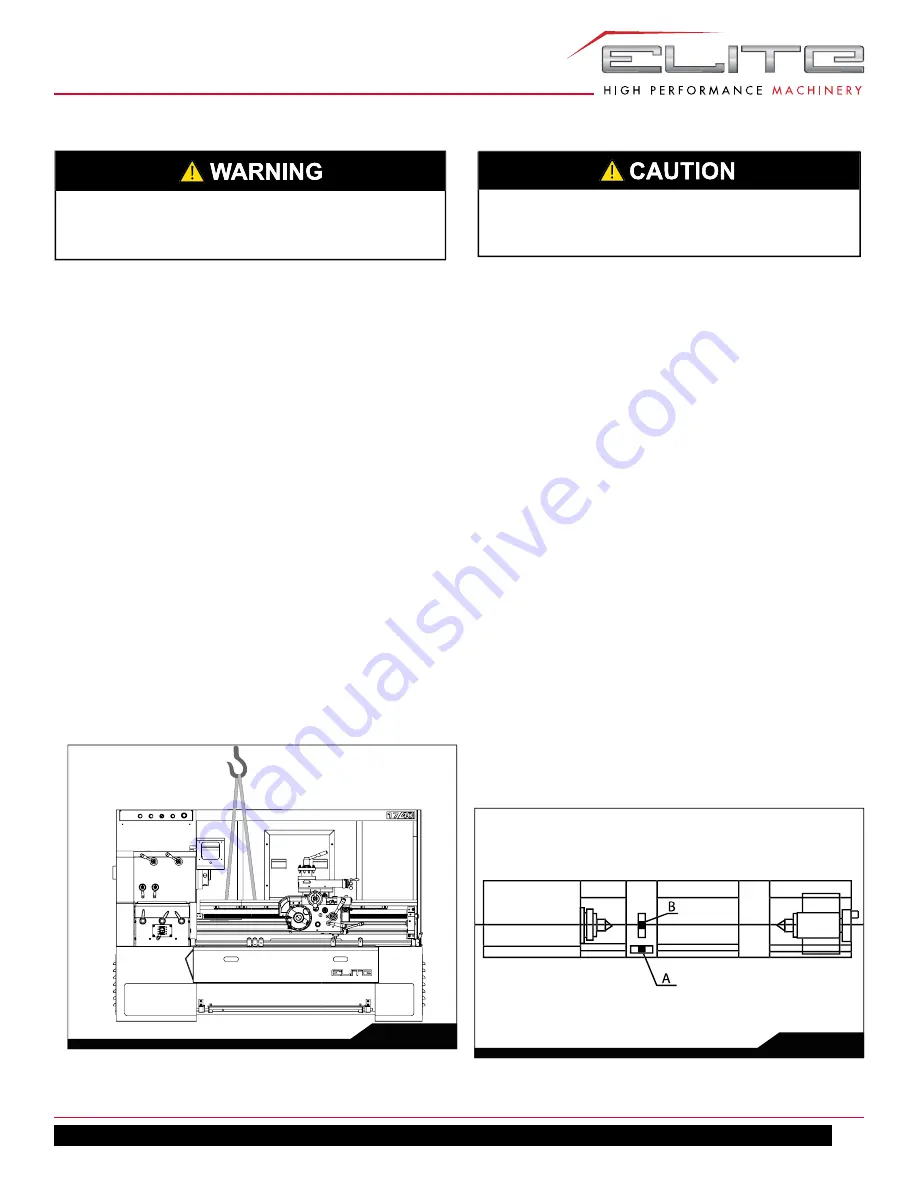

9. Use a machinist’s precision level on the bed ways

both front to back and side to side, as shown in Fig-

ure 7. Take the reading in one direction every ten

inches. Make sure the ways are clean and free of any

debris before placing a level upon them.

10. Deviation over bed length (see Figure 7):

(a) Maximum 0.02/1000mm

(b) Maximum 0.04/1000mm

Fig. 7

7.0 INSTALLATION

1. Finish removing all crate material from around lathe.

2. Unbolt lathe from shipping pallet.

3. Choose a location for the lathe that is dry and

has sufficient illumination (consult OSHA or ANSI

standards for recommended lighting levels in

workshop environments).

4. Allow enough room to service the lathe on all four

sides, and to load and off-load work pieces. In

addition, if bar work is to be performed, allow enough

space for stock to extend out the headstock end. If

used in production operations, leave enough space

for stacking unfinished and finished parts.

5. The foundation must be solid to support the weight of

the machine and prevent vibration, preferably a solid

concrete floor.

6. The lathe’s center of weight is near the headstock.

Before lifting, move the tailstock and the carriage to

the right end of the bed and lock them.

7. With properly rated lifting equipment, slowly raise

lathe off shipping pallet. (see Figure 6). Do not lift

lathe by the spindle.

Fig. 6

Summary of Contents for 892100

Page 21: ...21 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 22: ...22 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 23: ...23 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 24: ...24 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 28: ...28 1700 Series Lathe GEARBOX ASSEMBLY ...

Page 29: ...29 EGH1740 EGH1760 GEARBOX ASSEMBLY ...

Page 33: ...33 EGH1740 EGH1760 APRON L H ASSEMBLY ...

Page 34: ...34 1700 Series Lathe APRON L H ASSEMBLY ...

Page 39: ...39 EGH1740 EGH1760 4 WAY TOOL POST ...

Page 41: ...41 EGH1740 EGH1760 SADDLES ASSEMBLY ...

Page 42: ...42 1700 Series Lathe SADDLES ASSEMBLY 2 ...

Page 45: ...45 EGH1740 EGH1760 BED AND SHAFTS ASSEMBLY ...

Page 48: ...48 1700 Series Lathe END GEAR ASSEMBLY ...

Page 50: ...50 1700 Series Lathe MAIN MOTOR ASSEMBLY ...

Page 52: ...52 1700 Series Lathe CABINET AND PANEL ASSEMBLY FRONT MOVEABLE CHIP TRAY OPTIONS ...

Page 56: ...56 1700 Series Lathe CONVENTIONAL TAILSTOCK ASSEMBLY ...

Page 58: ...58 1700 Series Lathe STEADY REST ASSEMBLY ...

Page 62: ...62 1700 Series Lathe 892156 5C COLLET CLOSER OPTIONAL ...

Page 64: ...64 1700 Series Lathe 892157 TAPER ATTACHMENT OPTIONAL ...