10

1700 Series Lathe

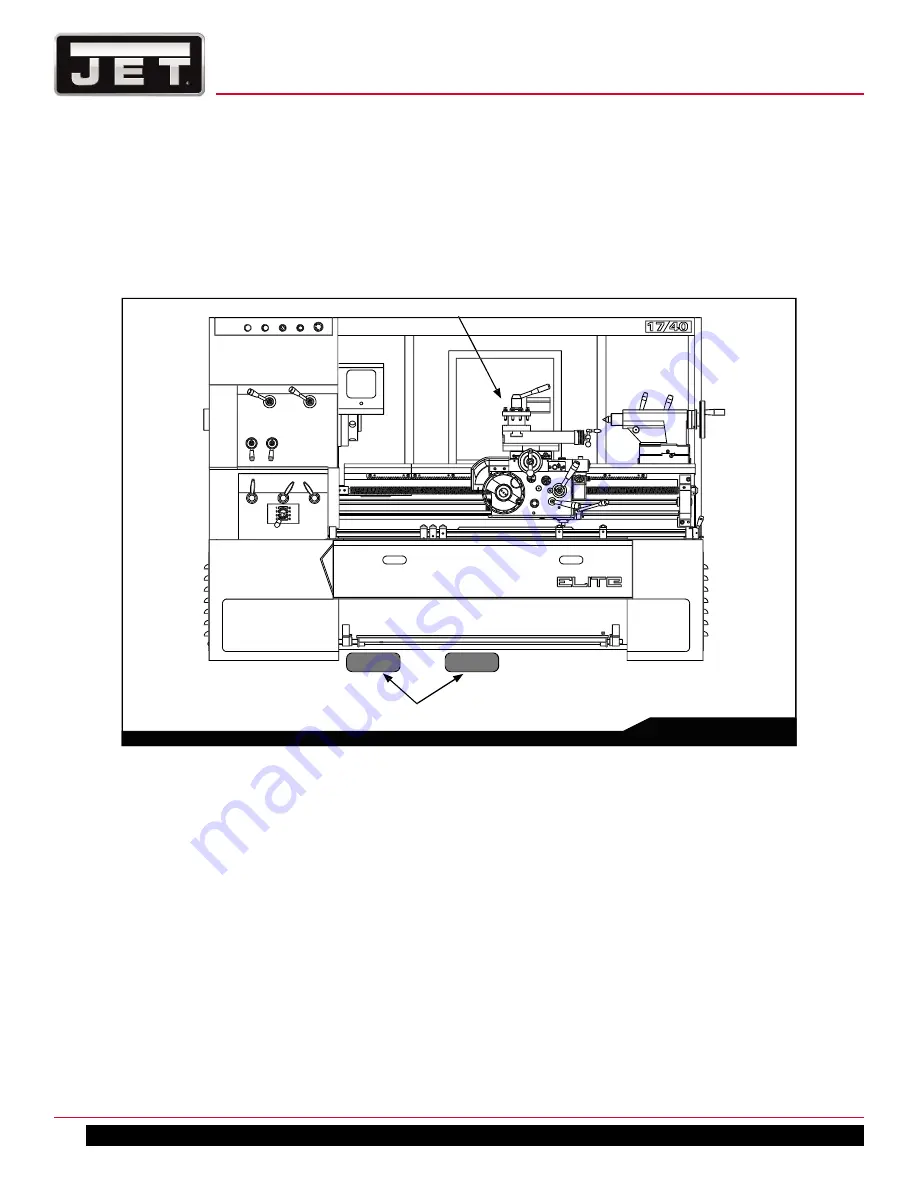

Fig. 5

•

Make sure that the minimum forklift capacity is

more than 3 tons.

•

Forklift work should be done by two people, an

operator and watchman.

6.3 MOVING THE MACHINE WITH A FORKLIFT

Preparation:

1. Ensure the power is disconnected from machine.

2. Move the saddle and tailstock to the far right side of

machine in order to achieve balance.

•

Insert forks under the bed as close to the

headstock as possible.

•

Make sure to keep the machine’s center of

gravity spread evenly across the forks.

3. Ensure that tailstock and saddle are firmly locked

into place before attempting to move machine.

Forklift

Hexagon socket head bolt

Summary of Contents for 892100

Page 21: ...21 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 22: ...22 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 23: ...23 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Page 24: ...24 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Page 28: ...28 1700 Series Lathe GEARBOX ASSEMBLY ...

Page 29: ...29 EGH1740 EGH1760 GEARBOX ASSEMBLY ...

Page 33: ...33 EGH1740 EGH1760 APRON L H ASSEMBLY ...

Page 34: ...34 1700 Series Lathe APRON L H ASSEMBLY ...

Page 39: ...39 EGH1740 EGH1760 4 WAY TOOL POST ...

Page 41: ...41 EGH1740 EGH1760 SADDLES ASSEMBLY ...

Page 42: ...42 1700 Series Lathe SADDLES ASSEMBLY 2 ...

Page 45: ...45 EGH1740 EGH1760 BED AND SHAFTS ASSEMBLY ...

Page 48: ...48 1700 Series Lathe END GEAR ASSEMBLY ...

Page 50: ...50 1700 Series Lathe MAIN MOTOR ASSEMBLY ...

Page 52: ...52 1700 Series Lathe CABINET AND PANEL ASSEMBLY FRONT MOVEABLE CHIP TRAY OPTIONS ...

Page 56: ...56 1700 Series Lathe CONVENTIONAL TAILSTOCK ASSEMBLY ...

Page 58: ...58 1700 Series Lathe STEADY REST ASSEMBLY ...

Page 62: ...62 1700 Series Lathe 892156 5C COLLET CLOSER OPTIONAL ...

Page 64: ...64 1700 Series Lathe 892157 TAPER ATTACHMENT OPTIONAL ...