500 795/Rev D/07-14

Page 35

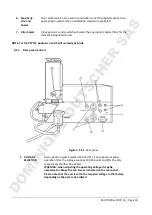

6. Depress the ignition switch and hold down. Watch the

FLM

indicator in the

window. When this indicator is illuminated the flame is a light and the ignition switch

be released. If the

FLM

indicator does not light within approximately 20

release the switch and open the

fuel

valve one additional turn. Allow the gas to disperse

continuing. Depress the ignition switch for a further 20 seconds. This process may

repeated until successful ignition occurs. If the

fuel

valve has to be opened more than

turns more than recommended above, refer to Section

7. Set the

filter select

control to the desired

8. Aspirate deionised water and set the readout to zero by adjusting the

blank

9. Aspirate a standard solution of slightly higher concentration than expected in

samples to be tested. Adjust the

fine and coarse

control until a positive reading

obtained. This is a nominal value to be used in optimising flame

10. Adjust the

fuel

valve in a clockwise direction until a peak reading is

NOTE: There is a time delay between adjusting the flow of fuel and

the

effect of the adjustment. A pause of a few seconds is

necessary

between making every fine

The optimum flame conditions are different for Na and K

retuning is necessary when switching between

11. For optimum performance the instrument should be allowed 15 minutes to

During this warm-up period a blank deionised water sample should be aspirated.

should be noted that results, adequate for most purposes, can be obtained from

on, although standardisation settings will need frequent checking during the

DOMINIQUE DUTSCHER SAS