500 795/Rev D/07-14

Page 34

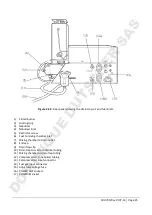

2.

FUSES

Two fuses are fitted to the instrument.

FS1

is the primary fuse provided

to protect the instrument and any accessories connected to the

power

out

sockets.

FS2

is to protect the electronic circuitry in the PFP7. Both

FS1 and FS2 should be of an anti-surge type.

3.

POWER IN

A three pin receptacle for the AC mains supply.

4.

POWER OUT

Two three pin sockets for flame photometer accessories such as a

compressor. The power from these sockets is controlled by the

instrument

power

switch on the front panel.

5.

RECORDER

Two 4mm sockets which will provide an analogue signal of

approximately 1 volt when the readout is 1000 digits or 100.0, 10.00,

1.000.

6.

FUEL GAS

1/4" connector for fuel tubing.

IMPORTANT: Fuel supply must be regulated to 10-15 inches water

gauge (0.36-0.54psi or 0.025-0.38kg/cm

2

. See section 2.1.2 for

information on different fuel types.

7.

AIR

5/16" connector for air tubing.

IMPORTANT: Air pressure on the inlet to the instrument must not

exceed 30psi (2kg/cm

2

). See section 2.1.3.

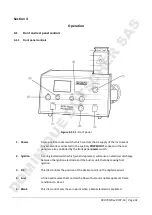

4.2

Operation Flame Ignition and Optimisation

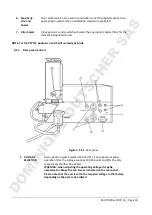

1. Ensure that the drain trap is pushed fully down on its clip. Ensure that the drain trap

solution in it and that no air locks are present. If necessary, purge by adding

water and allowing the surplus to run

2. Close the

fuel

valve by turning fully clockwise. To avoid damaging the valve, it

not

be

3. Turn the

fuel

valve the required number of turns anti-clockwise depending on the

being

Fuel Number of

Propane

Butane

Natural gas Fully

L.P.G.

4. Turn on the fuel supply at source i.e.

5. Switch on electrical power by depressing the

power

switch. If the air compressor is

powered separately, switch on the air compressor. Ensure that air is present

listening for the hissing created as it passes through the

DOMINIQUE DUTSCHER SAS