During the steam bath treatment, the time can always be varied by pressing the (+) and (-) buttons without interrupting

the functions. Also for your convenience, a buzzer will sound when the steam timer reaches zero (00). There is a 10

second delay before the steam bath function is cancelled. During this delay the timer can be reset to allow more steam

bath operation. The steam bath function is controlled with a safety device (indicated by a faucet with a water drop

symbol on the display). This safety device operates in the event that water has been turned off before the steam timer

reaches 00. If the steam water level drops below the minimum level, the red light (13, Figure 1) above the faucet symbol

will come on and an audible signal will sound warning that the water flow from mixer Y has stopped. This occurs

approximately 5 minutes after the flow has ceased. If water is not restored to the steamer unit at this time, the steam

bath function will be cancelled.

The electronic device has a self test program which checks all functions when the power is turned on. All the lights

on the display turn on in a programmed test sequence lasting 8 seconds and testing 14 events. The end of the test

sequence leaves the steam digital time display (Figure 1) reading (--).

In case of power failure while the J-Dream is operating, any function will be completely cancelled. When power is

restored, the self test will activate and any function can be reset at this time.

The electronic unit is equipped with an internal safety program which automatically cancels any function if a program

has not been completed within 60 minutes.

Before changing from the hydromassage to the steam bath function, or vice versa, the water in the holding tank will

be automatically exchanged, which requires approximately a 60 second waiting period. This feature is incorporated

to decrease deposit buildups in the steam generator.

Use the hand shower while steam is operating

Follow the steps below to operate the hand shower during steam operation without turning off the steam function. This

procedure avoids the drain/fill/heat-up cycle that occurs when the steam control is turned off and back on again at the

control panel.

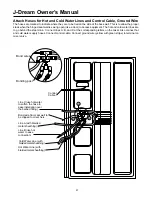

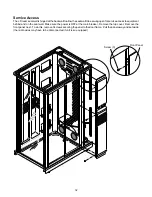

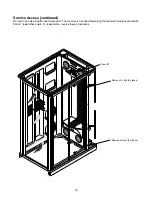

1. During normal steam operation, the transfer valve is in the middle position as shown in Figure 2 and the mixer valve

is open, or “ON”.

2. Without changing the electronic control panel settings, turn the transfer valve handle to the “handshower”

position. Water will flow from the handshower, and the mixer handle may be used to adjust the water temperature.

The steam mode will continue to function.

3. When you have finished cooling down or rinsing off with the handshower, turn the transfer valve handle back to the

middle position leaving the mixer handle “ON”.

The water flow will stop at the hand shower, and the mixer valve will then continue to provide water to the steam

generator as required.

30