11

07610-002-23-32-AD

Electrical and grounding conductors must comply with the applicable portions of the

National Electric Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

The data plate is located on the right side of the machine. Refer to the data plate for

machine operating requirements, machine voltage, total amperage, and serial number.

1. Open the control box by using a phillips screwdriver to remove the four screws on

the front cover of the control box.

2.

Install 3/4” conduit into the pre-punched holes in the back of the control box.

3.

Route power wires and connect to power block and grounding lug.

4. Install the service wires (L3 for 3-Phase only) to the appropriate terminals as they

are marked on the terminal block.

5. Install the grounding wire into the lug provided.

6. Tighten the connections.

“DE-OX” or similar anti-oxidation agent should be used on all power

connections.

CAUTION!

Improperly connecting external devices can cause damage to the

machine and/or electrical infrastructure! Click

here

for a wiring guide.

On 3-Phase machines only, correct pump motor rotation must be verified before

the machine is operated. Failure to do so can result in damage to the machine and

components.

1. Follow the "Filling the Wash Tub" section.

2. Locate the wash pump motor and identify the arrow decal which shows the

correct motor rotation.

3.

Flip the mode switch to "MANUAL" and start the machine.

4.

Observe the rotation of impeller and quickly stop the machine.

5. If rotation is incorrect, disconnect electrical power and reverse the

L1 and L2 connections at terminal block shown in the section above.

ELECTRICAL POWER

CONNECTIONS

Disconnect electrical

power supplies and

lockout/tagout in

accordance with

appropriate procedures

and codes at the

disconnect switch.

!

CAUTION

INSTRUCTIONS

INSTALLATION

Imbalanced

wild leg goes

to L3.

NOTICE

L1

L2

L3

Ground

3

Φ

NOTICE

MOTOR ROTATION

i

CAUTION!

On 3-Phase

machines only, correct

pump motor rotation

must be verified

before operation!

!

CAUTION

Rotation

Impeller

Summary of Contents for TEMPSTAR HH S

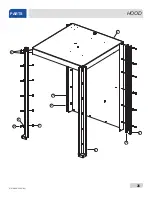

Page 35: ...07610 002 23 32 AD 26 1 5 4 2 3 6 7 10 8 9 HOOD PARTS ...

Page 61: ...07610 002 23 32 AD 52 VER SYSTEM PARTS 18 24 23 12 11 16 17 14 21 22 20 19 27 28 29 ...

Page 67: ...07610 002 23 32 AD 58 SCHEMATICS HH E VER 208 230 V NEW RINSE TANK ...

Page 68: ...59 07610 002 23 32 AD SCHEMATICS HH E VER 460 V NEW RINSE TANK ...

Page 69: ...07610 002 23 32 AD 60 SCHEMATICS HH E VER 208 230 V OLD RINSE TANK ...

Page 70: ...61 07610 002 23 32 AD SCHEMATICS HH E VER 460 V OLD RINSE TANK ...

Page 71: ...07610 002 23 32 AD 62 SCHEMATICS NB 208 230 V ...

Page 72: ...63 07610 002 23 32 AD SCHEMATICS NB 460 V ...

Page 73: ...07610 002 23 32 AD 64 SCHEMATICS HH S 208 230 V ...

Page 74: ...65 07610 002 23 32 AD SCHEMATICS SDI OPTIONS ...

Page 75: ......