PREPARATION:

Before proceeding with the start-up of the unit, verify the following:

1. Close door(s) on dishmachine.

2. Close the drain valve(s).

POWER UP (ELECTRICALLY-HEATED MODELS):

To energize the unit, turn on the power at the service breaker. The volt-

age should have been previously verified as being correct. If not, the voltage will have to be verified.

POWER UP (STEAM-HEATED MODELS):

To energize the unit, turn on the power at the service breaker. The voltage should

have been previously verified as being correct. If not, the voltage will have to be verified. Ensure that the steam service is con-

nected and that steam is flowing to the machine. Without steam, the water will not reach the required minimum temperatures

that the machine is designed to operate at.

FILLING THE WASH TUB:

Ensure that the delime switch is in the NORMAL position, and place the power switch into the ON

position. The machine should fill automatically and shut off when the appropriate level is reached (just below the pan strainer).

The wash tub must be completely filled before operating the wash pump to prevent damage to the component. Once the wash

tub is filled, the unit is ready for operation.

Machines equipped with prewash sections should not be run without water in those sections. This can cause damage

to components.

WARE PREPARATION:

Proper preparation of ware will help ensure good results and less re-washes. If not done properly, ware

may not come out clean and the efficiency of the dishmachine will be reduced. It is important to remember that a dishmachine

is not a garbage disposal and that simply throwing unscraped dishes into the machine simply defeats the purpose alto-

gether of washing the ware. Scraps should be removed from ware prior to being loaded into a rack. Pre-rinsing and pre-

soaking are good ideas, especially for silverware and casserole dishes. Place cups and glasses upside down in racks so

that they do not hold water during the cycle. The dishmachine is meant not only to clean, but to sanitize as well, to destroy all

of the bacteria that could be harmful to human beings. In order to do this, ware must be properly prepared prior to being placed

in the machine.

DAILY MACHINE PREPARATION:

Refer to the section entitled “PREPARATION” at the top of this page and follow the instruc-

tions there. Afterwards, check that all of the chemical levels are correct and/or that there is plenty of detergent available for the

expected workload.

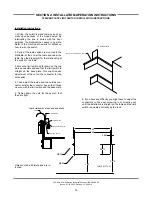

WASHING A RACK OF WARE:

To wash a rack, simply slide a rack of soiled ware into the load end of the machine. Once the

the machine is started, it should pull the rack through the machine and push it out the unload end. Once a rack has started

through, you may put another rack in.

OPERATIONAL INSPECTION:

Based upon usage, the pan strainers may become clogged with soil and debris as the work-

day progresses. Operators should regularly inspect the pan strainers to ensure they have not become clogged. If the strainers

do, they will reduce the washing capability of the machine. Instruct operators to clean out the pan strainers at regular intervals

or as required by work load.

NOTE: On units equipped with prewash sections (AJX-66, AJX-76, AJX-80 & AJX-90), operators should also take the time to

inspect the prewash section strainers and clean them as required by workload.

SHUTDOWN AND CLEANING (ELECTRICALLY-HEATED MODELS):

At the end of the workday, place the power switch in

the OFF position and open the door(s). Open the drain valves and allow the machine to drain completely. Remove the pawl bar

assembly (clean as required). Remove the pan strainers and, if equipped, the prewash strainers, run off sheets and scrap bas-

AJX-44 & AJX-54 Series Technical Manual 7610-003-60-98

Issued: 01-19-2009 Revised: 01-30-2009

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

DISHMACHINE OPERATING INSTRUCTIONS

27

Summary of Contents for AJX-44 Series

Page 8: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Page 27: ...20 SECTION 2 INSTALLATION OPERATION INSTRUCTIONS ...

Page 38: ...31 SECTION 3 PREVENTATIVE MAINTENANCE ...

Page 42: ...35 SECTION 4 TROUBLESHOOTING SECTION ...

Page 45: ...38 SECTION 5 PARTS SECTION ...

Page 92: ...85 SECTION 6 ELECTRICAL SCHEMATICS ...

Page 103: ...96 SECTION 7 JACKSON MAINTENANCE REPAIR CENTERS ...

Page 110: ...AJ 44T Series Technical Manual 7610 003 07 21 Issued 03 21 2006 Revised N A ...