34

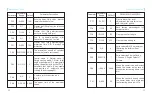

Err-01

Err-02

Err-03

Err-04

Err-05

Err-06

Turn off the power switch, and restart after

30 seconds. If the controller still does not

work, please replace it and inform the

manufacturer.

Disconnect the controller power and

check if the input voltage is too low

(lower than 176V). If yes, please restart

the controller when the normal voltage is

resumed. If the controller still does not

work when the voltage is at normal

level, please replace the controller and

inform the manufacturer.

Turn off the system power to detect if

electromagnet connection is correct,

whether there is loose, damaged

phenomenon. If yes, replace it in time.

Restart the system after confirmation, if it

still does not work, please replace the

controller and inform the manufacturer.

35

10

11

12

13

20

21

22

23

24

25

26

27

28

29

02A

02B

02C

02D

030-037

Error

Code

Description

Solution

Hardware

overcurrent

Software

overcurrent

Over-voltage

in operation

Disconnect the controller power and

check if the input voltage is too high

(higher than 264V). If yes, please restart

the controller when the normal voltage is

resumed. If the controller still does not

work when the voltage is at normal level,

please replace the controller and inform

the manufacturer.

Solenoid

Short circuit

Parameter

Parameter

Description

DC voltage

Machine speed

The phase current

Error Counter

QP Superstate

Machine angle

Parameter

Description

Parameter

stitch counter

The ratio between

motor and machine

Counter for sewing

pieces

The total used time

(hours) of motor

real speed of the

head

The sampling voltage

of interaction

State of encoder

DSP Software version

S i m u l a t e i n p u t i n g

sampled value 1

S i m u l a t e i n p u t i n g

sampled value 2

The history record of

error codes

The sampling

voltage of pedal

Control box panel

version

P+

free sewing

Initial electrical

angle

system under

voltage

ver-voltage

when the

machine is off

Manual Book of A4

Error Code

Summary of Contents for A4

Page 21: ...Notes Notes...

Page 22: ...Notes Notes...