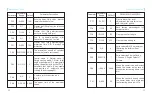

Err-12

Err-13

Err-14

Err-15

36

Err-07

Turn off the system power, restart after

30 seconds to see if it works well. If

such failure happens frequently, seek

technical support.

。

Err-08

- Eliminate sluggish movement in the

sewing machine

- Replace encoder - Replace sewing

motor

Err-09

Check the brake resistor plug on the

electric board. Replace the control

box

。

Err-10

Check the connection and if necessary

plug in. Replace the control box.

Err-11

Check if the connection line between

machine head synchronize rand

controller is loose or not, restore it and

restart the system. If it still does not

work, please replace the controller and

inform the manufacturer.

Error

Code

Description

Solution

Motor current

measuring

failure

Brake circuit

failure

Communicati

on failure

Machine

head needle

positioning

failure

Error

Code

Description

Solution

Initial motor

electrical angle

failure

- Try 2 to 3 more times after power

down

-if it still does not work, please replace

t h e c o n t r o l l e r a n d i n f o r m t h e

manufacturer.

Motor hall

failure

Turn off the system power, check if the

motor sensor plug is loose or dropped

off, restore it and restart the system. If

it still does not work, please replace

t h e c o n t r o l l e r a n d i n f o r m t h e

manufacturer.

Dsp

read/write

eeprom

failure

Motor over-

speed

protection

Err-16

Motor

reversion

Hmi

read/write

eeprom

failure

Err-17

Err-18

Err-23

Motor overload

Turn off the system power, restart the

system after 30 seconds, if it still does

not work, please replace the controller

and inform the manufacturer.

Sewing motor

blocked encoder

failure

- Eliminate sluggish movement in the

sewing machine

- Replace encoder - Replace sewing

motor

R

Switch alarm

Straighten the handpiece, to ensure

that the switch recovery

Sewing

motor

blocked

Manual Book of A4

Error Code

Summary of Contents for A4

Page 21: ...Notes Notes...

Page 22: ...Notes Notes...