40

9.4 Control of air volume

The air volume is determined by the speed of the impeller and the underpres-

sure in the mounting curb, see the graph §4.1.

The speed can be determined by:

• measuring with the aid of a stroboscope;

• reading the speed with the VU Control Unit in the ‘Status’ menu under

‘Speed’.

• measuring the voltage on the ‘Esoll’ and ‘GND U3’ clamps and plotting

these measured values in the applicable graph on page 14. These graphs

only apply if the MX has been set at minimum speed 15%* and maximum

speed 100% [this is the standard factory setting]. If these settings are

different, the applicable graph must be adjusted accordingly. This method

is not applicable for ZMV.

*The minimum capacity of the MX 30/20 has been factory set at 25%.

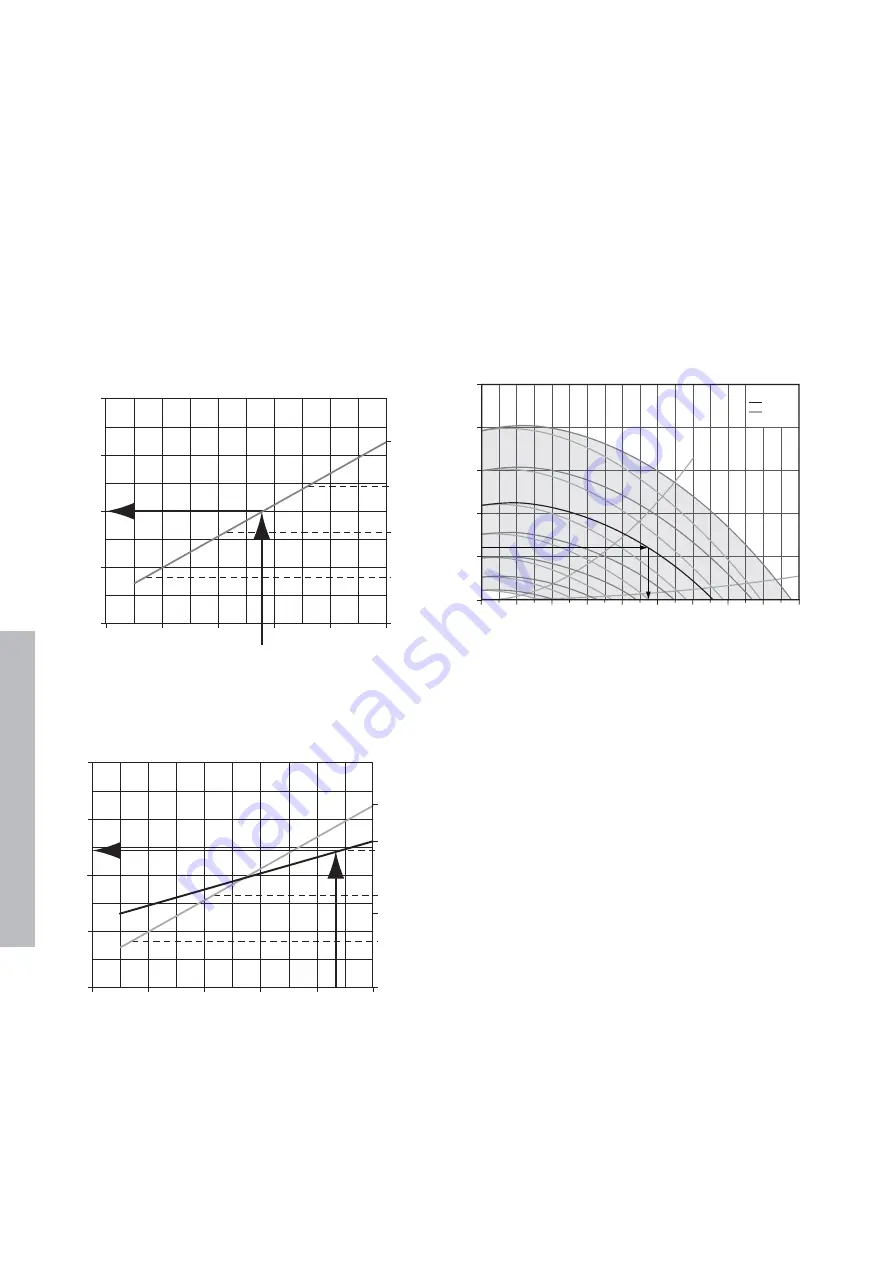

Example: MX 20/10

Speed rpm [min-1]

Capacity [%]

Measured voltage 5.5V

Speed is 1000rpm

Example: MX 20/10

Speed rpm [min-1]

Capacity [%]

Speed rpm 9 [min-1] Capacity [%]

Minimum capacity setting 40%

Maximum capacity setting 80%

Measured voltage 8.7 V

Speed is 1200 rpm

The underpressure can be determined by:

• measuring the underpressure in the mounting curb;

• reading the underpressure with the VU Control Unit in the ‘Status’ menu

under ‘Sensor’. However: this is only possible for the ZMV and when the

measuring point of the pressure transmitter is located in the mounting curb.

The air volume can now be determined.

• Now plot the speed line found in the graph §4.1.

☞

Take notice of that you use the line with or without silencer [GD]?

• Now draw a line from the underpressure found to the right.

• Draw a line vertically from the intersecting point found and determine the

air volume.

Example

A. = maximum power consumption and B = maximum sound pressure level

Example

Speed 1200 rpm

No silencer

Underpressure 120 Pa

Air volume is 1900 m3/h

Conclusions

More air than the design value means that the resistance in the system is

lower than the design value.

Possible causes are:

• lower duct resistance than assumed;

• valves or grilles have not be fitted or adjusted [open too far];

• leakage in the duct system. Compare the air volume with the total

measured air volume through the valves.

Less air than the design value means that the resistance in the system is

higher than the design value.

Possible causes are:

• higher duct resistance than assumed;

• valves or grille not adjusted [too far closed];

• blockage in the duct system. Compare the air volume with the total

measured air volume through the valves.

500

400

300

200

100

0

0

400

800

1200 1600

1600

1400

1200

1000

800

600

400

A

B

2000 2400 2800

3200

3600

m

3

/h

∆

Pst - Pa (N/m

2

)

= MX

= MX + GD

2000

1500

1000

500

0

0

2

4

6

8

10

E

soll

- GND (V)

0

25

50

75

100

80

40

2000

1500

1000

500

0

0

2

4

6

8

10

E

soll

- GND (V)

0

25

50

75

100

English