15

6X-1050a

3960 CAMERA

INSTALLATION AND OPERATION

room air (which typically has a high relative humid-

ity) by flowing dry nitrogen into the Schrader valve

and out the pressure relief valve. This relief valve

should be held open to aid in the flow of nitrogen

out of the camera.

This purging process removes moist room air

from inside the camera and provides an internal

relative humidity of five percent or less. A camera is

typically pressurized to 5 psig (34 kPa). Pressure

can be allowed to go below this — even down to

one or two pounds so long as the pressure does not

ever become zero. An occasional recharge of dry

nitrogen can be used to maintain pressure near 5

psig (34 kPa). If pressure continually drops it is an

indication of a slow leak. These pressure refer-

ences are gauge pressures (psig). They are relative

to the altitude above sea level at which they are

being measured.

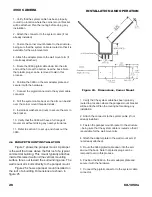

2.8.1.2 Pressure Relief Valve

The pressure relief valve opens at about 20

psig (138 kPa). This relief pressure allows the 3960

to be taken to high altitude during transportation

without excess bleed off of dry nitrogen from the

camera housing. If the camera module should loose

some dry nitrogen during high altitude transporta-

tion (as indicated by a pressure reading below

about 5 psig) then some additional dry nitrogen may

be added to replenish the lost nitrogen.

This valve should be manually lifted off its seat

or pushed slightly to the side when it is desired to

flow dry nitrogen through the camera to purge

moisture laden atmospheric air from the camera

module.

Regularly applying pressure above 5 to 8 psig

(35 to 55 kPa) may cause seals to weaken and

leak.

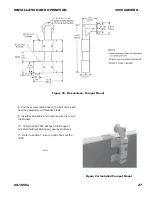

2.8.2 16-pin Connector

This connector is attached to the 34 inch (86

cm) long cable that is permanently attached to the

base of the 3960. Table 6 lists pin functions for a

115 V ac version of the 3960 and table 7 lists

functions for a 24 V ac version. Note that five of the

pins are not used — although different pins are

used to apply the line (hot) lead of 115 V ac and

one line of the 24 V ac power. The camera model

number identifies whether it is configured for 115 V

ac or 24 V ac operation.

Figure 10 is the pin location diagram of this

connector. It is a view from the mating side of the

connector. This view is identical to the wiring view of

a mating connector (supplied) for the system cable

that plugs into this 3960 connector.

The connector supplied for the system cable

should not be installed until it is verified that the

cable can be pulled through any conduit or other

restricted passage on its way to the mounting

location of the 3960.

2.9 Preparation for Shipment and Storage

Maintain the 3960 storage environment within

a range of -34 to 74 °C (-29 to 165 °F).

Figure 14. Camera Module Rear Panel

Figure 15. Model 9300 Local Control Panel (Optional Installation Equipment)