Ironwood JT400 | User Manual

20

7.3 Types of Cuts

Edge Jointing

Depth of cut should be the minimum required to obtain a straight

edge. Do not make cuts deeper than 1/8" (3.2mm) in a single

pass. Hold the best face of the workpiece firmly against the fence

throughout the feed.

Surfacing

Depth of cut should be the minimum required to obtain a straight

edge. Do not cut more than 1/16" (1.5mm) per pass to allow control

of the workpiece. Always use a hold-down device or push block

when surfacing short stock or stock less than 3" (7.6cm) thick.

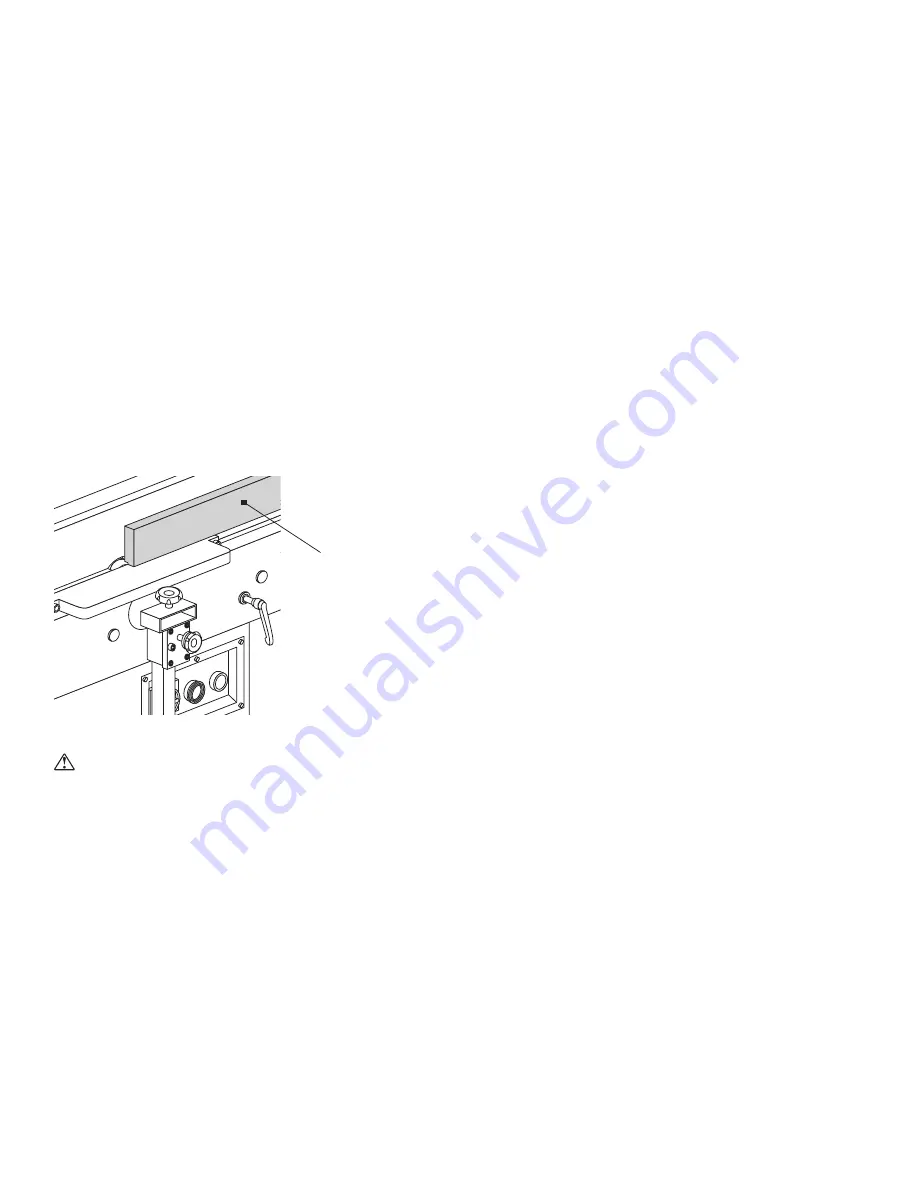

Rabbeting

The width and thickness of your workpiece is dependent upon

your preferred width and length of the rabbet (a groove cut along

the edge of a workpiece). Never rabbet a workpiece less than

12" (30.5cm) long.

Rabbeting

WaRninG

Rabbet cuts require removal of the cutterhead guard. Always

use extreme caution while rabbeting. Keep hands clear of the

cutterhead. When rabbeting is complete, immediately replace the

guard.

Jointing Warped Pieces

If the workpiece is deformed or warped, make shallow cuts with

multiple passes until the surface is flat. Do not force the workpiece

down against the table; excessive pressure prevents the jointer from

flattening the workpiece so it remains warped, curved, or cupped.

Jointing Short or Thin Workpieces

Always use a push block to prevent injury when jointing short or thin

workpieces.

Beveling

Lock the fence at the required angle, and keep the workpiece firmly

against the fence and tables. Several passes may be necessary to

remove enough material and achieve the desired result.

Taper Cutting

Lower the forward end of the workpiece onto the outfeed table

instead of starting the workpiece on the infeed table. Do this very

carefully, as the piece will span the cutterhead, which will begin

cutting at the point of contact with the workpiece. Firmly hold the

workpiece when placing it on the jointer to prevent kickback. Push

the workpiece forward as in ordinary jointing. The effect is to plane

off all the stock in front of the knives to increase depth, leaving a

tapered surface. The taper can be determined by the amount of

stock removal and the number of passes performed.

To remove any ridge left by the knives when starting the taper,

make a very light cut using the regular jointing method, with the

infeed table raised to its usual position. Practice is required for this

operation, and the beginner is advised to make trial cuts on waste

material.

Use extra precautions when performing such procedures.

Summary of Contents for JT400

Page 24: ...Ironwood JT400 User Manual 24 9 1 Electrical Print...

Page 25: ......