Ironwood JT400 | User Manual

16

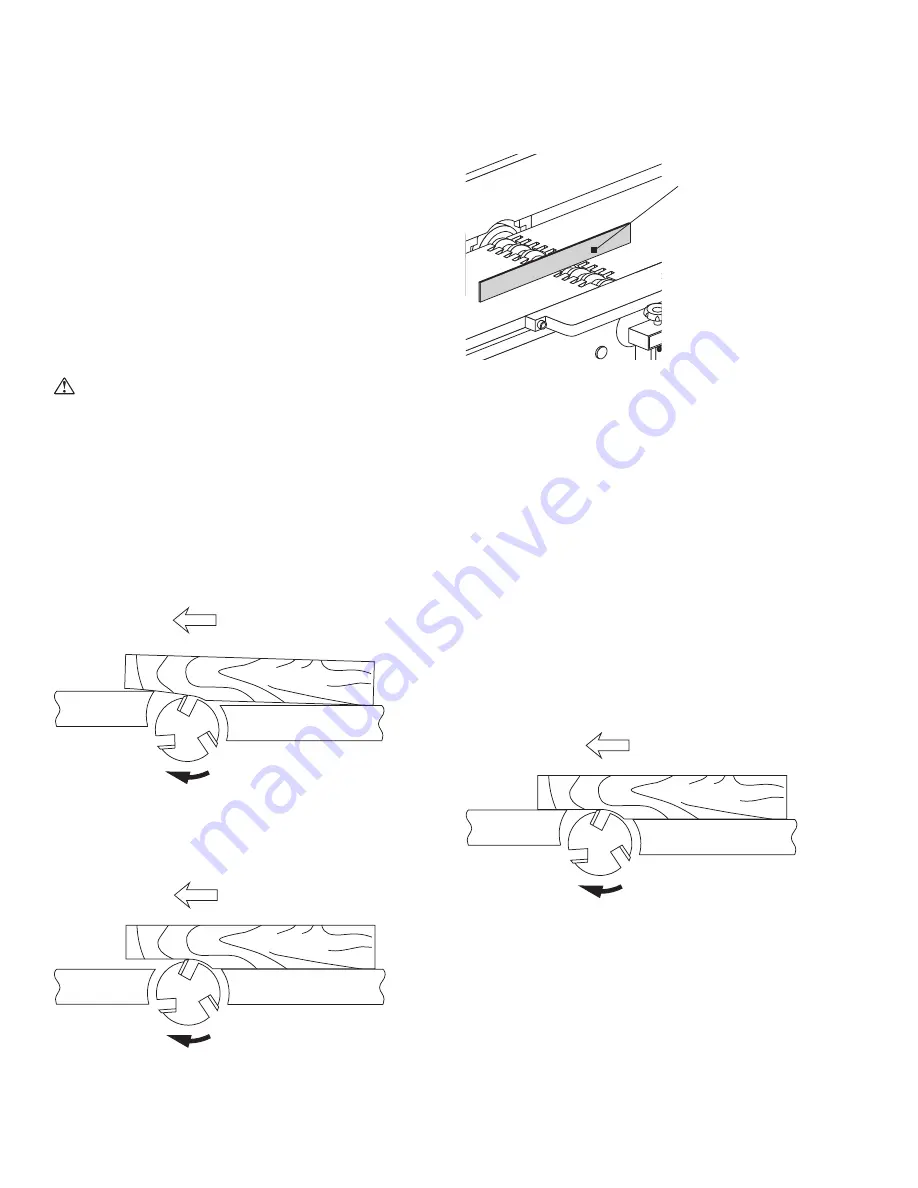

To remove and replace inserts, proceed as follows:

1. Loosen the knife gib by turning the Allen head screw in the

knife gib.

2. Remove the knife gib and knife.

3. Remove the remaining knives in the same manner.

4. Thoroughly clean the knife slots and knife gibs.

5. Check the screws. If they appear worn or stripped, replace

them.

6. In sequence, insert the knife and knife gib into the slot of the

cutterhead.

7. Fasten knife and gib with a spacer and Allen head screw.

8. Repeat the process until all knives are set in position and tight.

Step 3:

Align and Adjust Outfeed Table

Caution

The proper outfeed table height is preset at the factory. To ensure

the setting did not change during shipping, check outfeed table

height before you use the machine for the first time. Re-check

periodically.

For accurate work in most jointing operations, the outfeed table

must be exactly level with the knives at their highest point of

revolution.

If the outfeed table is too high, the finished surface of the workpiece

will be curved.

Work Piece

Infeed Table

WRONG

Outfeed Table

Cutter

Head

If the outfeed table is too low, the work will be gouged or sniped at

the end of the cut.

Work Piece

Infeed Table

Outfeed Table

Cutter

Head

WRONG

To properly align the cutterhead with the outfeed table:

1. Place a straight edge on the outfeed table and over a knife

tip on the cutterhead. Be careful not to damage the carbide

inserts.

Verify blade height

with straight edge.

2. Carefully turn the cutterhead by hand.

• If a knife tip makes contact with the straight edge, but

the straight edge does not move, the outfeed table is set

properly.

• If a knife tip does not touch the straight edge, the outfeed

table is too high.

• If the straight edge lifts slightly when knife makes contact,

the table is set too low.

To adjust the outfeed table height:

1. Loosen the table lock lever.

2. Move the adjustment handle up or down.

3. Tighten the table lock lever.

As a final check, run a piece of wood slowly over the knives for 6 to

8 inches. The wood should rest firmly on both tables with no open

space under the finished cut.

Infeed Table

Outfeed Table

Cutter

Head

Work Piece

CORRECT

Summary of Contents for JT400

Page 24: ...Ironwood JT400 User Manual 24 9 1 Electrical Print...

Page 25: ......