42

11.6.2

Chemical cleaning

Chemical cleaning dissolves biological clogging (fouling) and mineral deposits (such as lime) trapped

inside of the hollow fibres. Chemical cleaning is done only if the flow is extremely reduced.

Intensive chemical cleaning of the membrane cartridge may be done in two ways:

In-Situ, directly in the bio reactor

External in a separate cleaning container

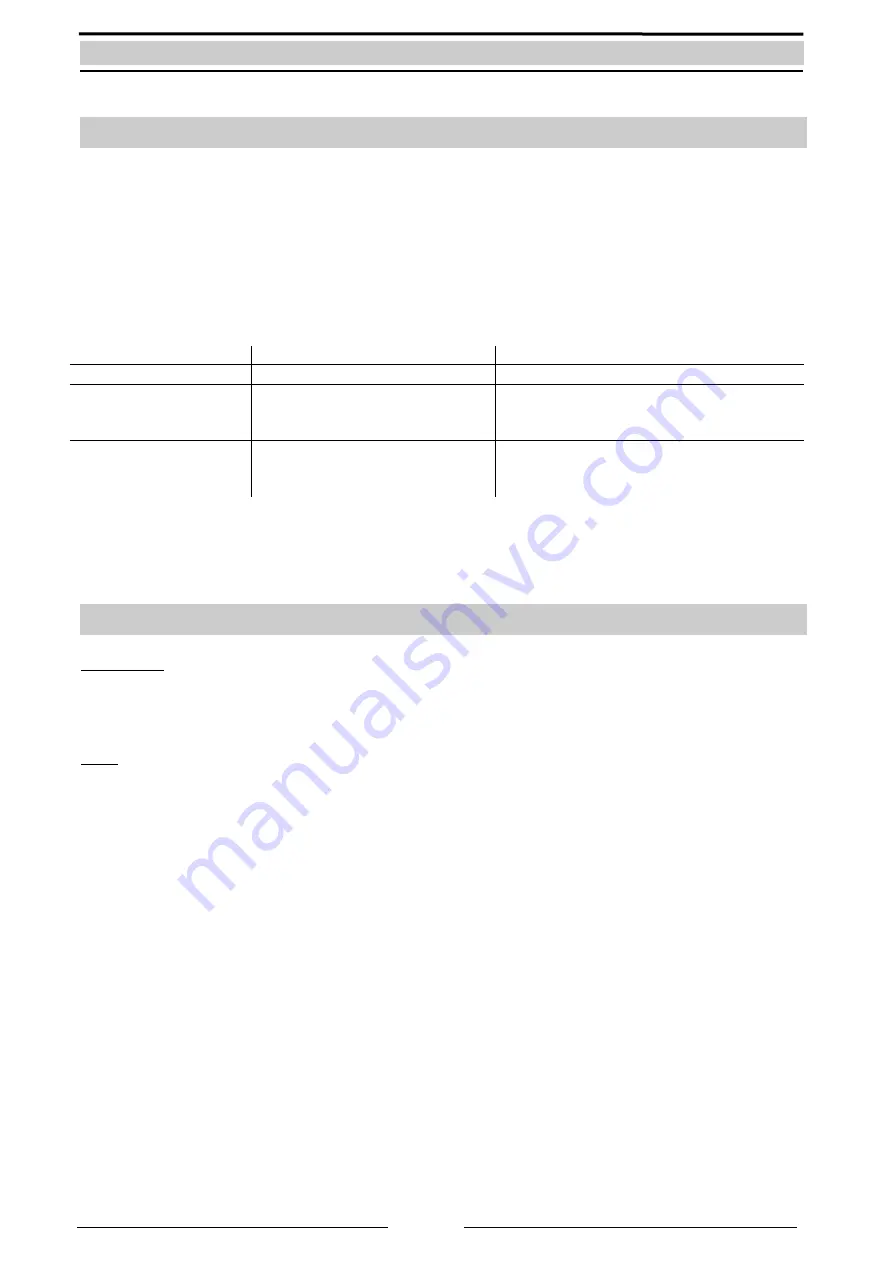

The main differences of the two cleaning possibilities are:

In-Situ cleaning

External cleaning

Cleaning time

1 hrs

12 - 24 hrs.

Cleaning result

(grey water application)

Depends on the state of the

membrane

up to 1.5 l/min

Independents of the state of the

membrane up to 2.0 l/min

Required accessories

Bracket and connection hose

separate cleaning container,

container size depends on the number of

membranes on the Membrane Station

11.6.2.1 In-Situ cleaning in the bioreactor

Description:

The Membrane Station remains in the bio reactor. For each membrane 2 litres of cleaning fluid are

poured into the back flush tank. With an automatic cleaning process controlled by the control unit the

membranes are cleaned for one hour. After the flushing with clear water the cleaning process is finished.

Note:

Throughout the chemical cleaning cycle the growth bodies can remain in the tank, the amount of

chlorine used does not affect the bacteria on the growth media, it removes only the biological

accumulations in the membrane. However, it is important that the amount of chlorine used shall not be

higher than directed.