Version 1.2 (08/2022) en

Translation of original operating instructions

23 of 40

Assembly and installation

6.4.3 External motor protection

The motor must always be installed together with suitable external motor protection, e.g., a motor circuit breaker

or frequency inverter with protection against excessive current. The protective device must be adjusted to the rated

current of the corresponding motor (see type plate).

6.4.4 Integrated thermal protection

CAUTION

Accidental motor start

Crushing hazard for fingers

¾

Connect the integrated thermal circuit breaker to an external control device that interrupts the current

supply to the motor at all poles in case of overheating.

¾

After the thermal circuit breaker has tripped, examine and remove the cause for overheating before the

current supply is reactivated.

The standard maximum switching current of the thermal circuit breaker is 2.5 A. For other options, please contact

Interroll.

For operational safety, the motor must be safeguarded against overload with an external motor protection, as well as

an integrated thermal protection; otherwise, there is no warranty if the motor fails.

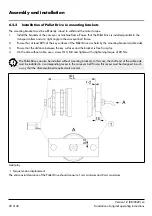

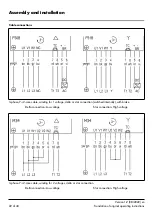

6.4.5 Frequency inverter

Asynchronous Pallet Drives can be operated with frequency inverters. Frequency inverters from Interroll are general

adjusted to factory setting and have to be parameterized for the respective Pallet Drive. For this purpose, Interroll can

supply parameterization instructions. In this case, please contact your local Interroll partner.

•

If no frequency inverter from Interroll is used, the frequency inverter must be correctly parameterized according to

the specified motor data. Interroll can provide only very limited support for frequency inverters that are not being

sold by Interroll.

• Resonance frequencies in the power supply line must be prevented since the create voltage spikes in the motor.

• If the cable is too long, frequency inverters generate resonance frequencies in the line between frequency inverter

and motor.

• Use a completely shielded cable to connect the frequency inverter to the motor.

•

Install a sine-wave filter or a motor choke if the cable is longer than 10 meter or if a frequency inverter controls

several motors.

• Ensure that the cable shield is connected to a grounded part according to the electrotechnical guidelines and local

EMC recommendations.

• Always observe the installation guidelines of the frequency inverter manufacturer.

Summary of Contents for DP 0080

Page 1: ...INSPIRED BY EFFICIENCY User Manual Interroll Pallet Drive DP 0080 DP 0089...

Page 38: ...38 of 40 Version 1 2 08 2022 en Translation of original operating instructions Appendix...

Page 39: ...Version 1 2 08 2022 en Translation of original operating instructions 39 of 40...

Page 40: ...INSPIREDBY EFFICIENCY 2022 INTERROLL EN 08 2022 Version 1 2...