16 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Options and accessories

4.2

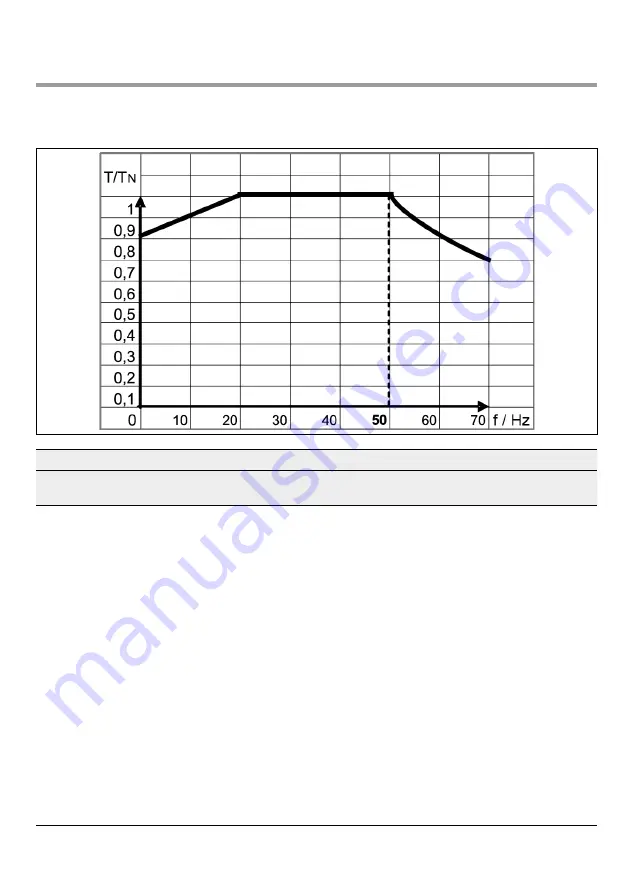

Asynchronous Pallet Drive with frequency inverters

4.2.1 Torque dependent on input frequency

Operating frequency [Hz]

5

10

15

20

25

30-50

Available motor torque in % of

rated motor frequency 50 Hz

80

85

90

95

100

100

The torque dependency depicted in the figure above is expressed as P = T x

ω

. With a reduced operating frequency

of below 20/24 Hz, the motor torque is reduced by changing heat dissipation conditions.

4.2.2 Frequency inverter parameters

Clock frequency:

A high clock frequency leads to a better utilization factor of the motor. Optimum frequencies are 8 or 16 kHz.

Parameters such as smooth running test quality (motor is running smoothly) and noise development are also affected

positively by high frequencies.

Voltage increase:

Interroll motor windings are designed for a rated voltage increase rate of 1 kV/μs. If a frequency inverter generates

a steeper voltage increase, motor chokes must be installed between the frequency inverter and the motor. However,

since all Interroll Pallet Drives run in an oil bath, the risk of overheating or damage to the motor due to high voltage

increase rates is extremely low. Contact your local Interroll dealer about the need for motor chokes.

Voltage:

If a frequency inverter with single-phase supply is installed in the Pallet Drive, the specified motor must be designed for

the frequency inverter output voltage and must be connected accordingly. Single-phase motors cannot be operated

with a frequency inverter.

Summary of Contents for DP 0080

Page 1: ...INSPIRED BY EFFICIENCY User Manual Interroll Pallet Drive DP 0080 DP 0089...

Page 38: ...38 of 40 Version 1 2 08 2022 en Translation of original operating instructions Appendix...

Page 39: ...Version 1 2 08 2022 en Translation of original operating instructions 39 of 40...

Page 40: ...INSPIREDBY EFFICIENCY 2022 INTERROLL EN 08 2022 Version 1 2...