23

441 01 5003 01

Specifications are subject to change without notice

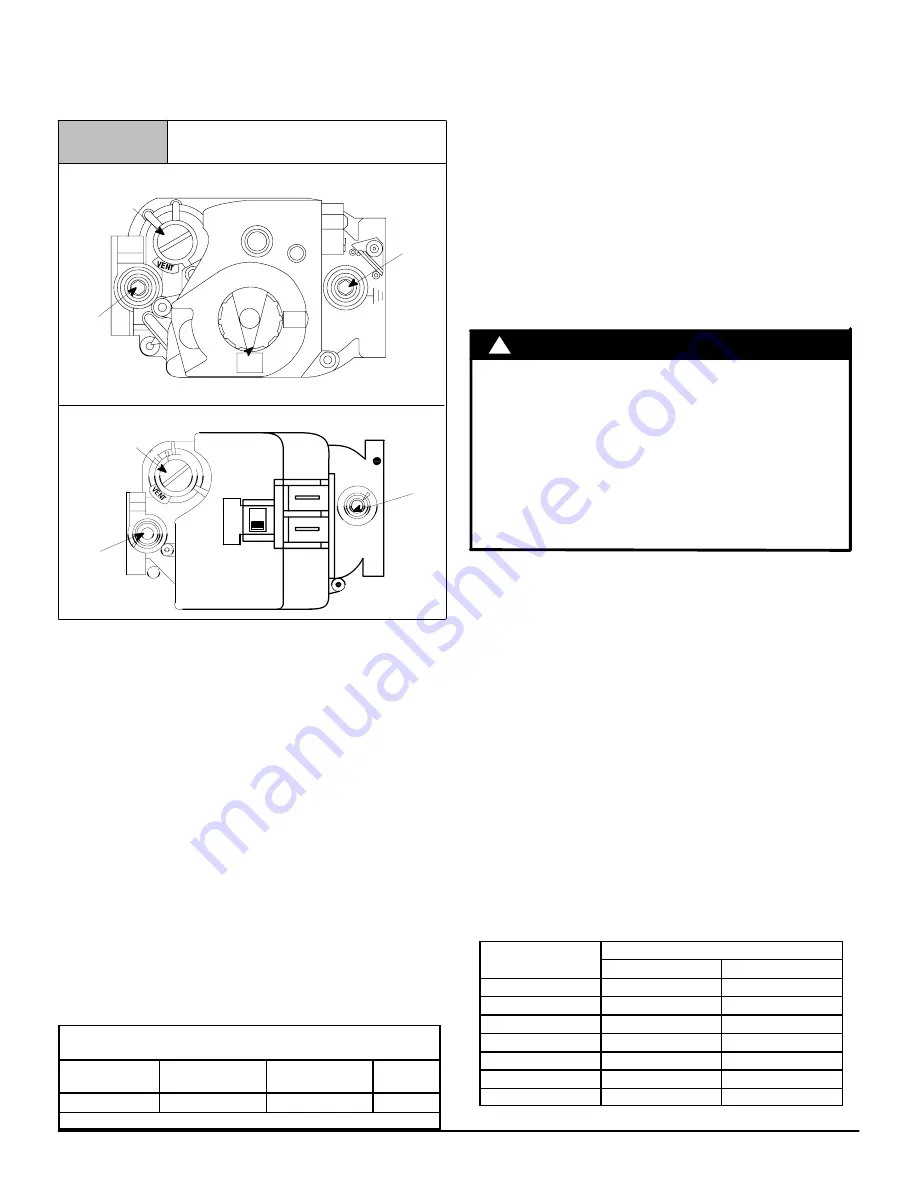

3.

Remove

manifold pressure adjustment screw cover on

furnace gas valve. Turn adjusting screw counterclockwise to

decrease manifold pressure and clockwise to increase

pressure.

Typical Gas Valve Honeywell

Figure 27

V

T

25--24--98a

HONEYWELL

ON

OFF

Regulator Adjustment

Under Cap

Inlet

Pressure

Tap

1

/

8

NPT

INLET

OUTLET

Outlet

Pressure

Tap

1

/

8

NPT

Regulator Adjustment

Under Cap

Inlet

Pressure

Tap

1

/

8

NPT

INLET

OUTLET

Outlet

Pressure

Tap

1

/

8

NPT

IN

OFF

ON

H

O

N

EYW

ELL

NOTE:

Adjustment screw cover

MUST

be replaced on gas valve

before reading manifold pressure and operating furnace.

4. Set manifold pressure to value shown in

Table 7

or

Table 8

.

5. When the manifold pressure is properly set, replace the

adjustment screw cover on the gas valve.

6. Remove jumper wire from thermostat connection on control

board.

Remove manometer connection from manifold

pressure tap, and replace plug in manifold.

7. Check for leaks at plug.

Natural Gas Input Rating Check

The gas meter can be used to measure input to furnace.

Check with gas supplier for actual BTU content.

1. Turn

OFF

gas supply to all appliances other than furnace and

start furnace. Use jumper wire on R to W.

2. Time how many seconds it takes the smallest dial on the gas

meter to make one complete revolution.

Note:

If meter uses a 2 cubic foot dial, divide results (seconds) by

two.

Refer to

Example.

The Example is based on a natural gas BTU

content of 1,000 BTU’s per cubic foot.

Example

Natural Gas

BTU Content

No. of Seconds

Per Hour

Time Per Cubic

Foot in Seconds

BTU Per

Hour

1,000

3,600

48

75,000

1,000 x 3,600

÷

48 = 75,000 BTUH

3. Remove jumper wire from R to W.

4. Relight all appliances.

Orifice Sizing

NOTE:

Factory sized orifices for natural and Propane gas are listed

in the furnace Technical Support Manual.

Ensure furnace is equipped with the correct main burner orifices.

Refer to

Table 5

,

Table 6

,

Table 7

or

Table 8

for correct orifice size

and manifold pressure for a given heating value and specific gravity

for natural and propane gas.

Operation Above 2000

′

Altitude

FIRE,

EXPLOSION,

CARBON

MONOXIDE

POISONING HAZARD.

Failure to follow these instructions exactly could

result in personal injury, death and/or property dam-

age.

This high--altitude gas--conversion shall be done by

a qualified service agency in accordance with the

Manufacturer’s instructions and all applicable

codes and requirements, or in the absence of local

codes, the applicable national codes.

!

WARNING

These furnace may be used at full input rating when installed at

altitudes up to 2000

′

. When installed above 2000

′

, the input must be

decreased 2% (natural) or 4% (Propane) for each 1000

′

above sea

level. This may be accomplished by a simple adjustment of

manifold pressure or an orifice change, or a combination of a

pressure adjustment and an orifice change. The changes required

depend on the installation altitude and the heating value of the fuel.

Table 5

&

Table 6

or

Table 7

&

Table 8

show the proper furnace

manifold pressure and gas orifice size to achieve proper

performance based on elevation above sea level for both natural

gas and propane gas.

To use the natural gas table, first consult your local gas utility for the

heating value of the gas supply. Select the heating value in the first

column and follow across the table until the appropriate elevation

for the installation is reached. The value in the box at the

intersection of the altitude and heating value provides not only the

manifold pressure but also the orifice size. In the natural gas tables

the factory--shipped orifice size is in bold (

42

). Other sizes must be

obtained from service parts.

High Altitude Input Rate =

Nameplate Sea Level Input Rate x (Multiplier)

Elevation

High Altitude Multiplier

Natural Gas

Propane Gas

0 - 2000

′

1.00

1.00

2001

′

- 3000

′

0.95

0.90

3001

′

- 4000

′

0.93

0.86

4001

′

- 5000

′

0.91

0.82

5001

′

- 6000

′

0.89

0.78

6001

′

- 7000

′

0.87

0.74

7001

′

- 8000

′

0.85

0.70

*

Based on mid--range of elevation.