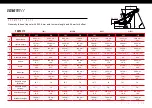

i n c l u d e d t o o l k i t

1. PH1 Philips driver

2. PH2 Philips driver

3. Long reach 5 mm HEX/Allen driver

4. Torque wrench extension

5. 2 mm HEX/Allen driver

6. 2.5 mm HEX/Allen driver

7. 3 mm HEX/Allen driver

8. 4 mm HEX/Allen driver

9. Flat head driver

10. 5 mm HEX/Allen driver

11. 6 mm HEX/Allen driver

12. 8 mm HEX/Allen driver

13. T25 Torx driver

14. T30 Torx driver

15. T40 Torx driver

16. 1/4" drive-to-1/4" drive bit adaptor

17. 1/4" drive-to-3/8" drive adaptor

18. Torque Wrench

19. 3-way Y-wrench Multi-HEX/

Allen tool (4 mm, 5 mm, 6 mm)

20. T25 Torx tool

21. INTENSE Shock Pump

22. Maxima grease

23. Tire plasma

1 8

//

2 0 2 1 p r i m e r u s e r m a n u a l

assembly

Preface //

Service and maintenance on an INTENSE cycle requires special tools,

abilities and knowledge of bicycle mechanics. Although each INTENSE

bicycle is supplied with a tool kit, it is recommended to use an authorized

INTENSE dealer for service and maintenance. Failure to follow these

instructions may result in serious bodily injury or death.

P r o t i p s

• Use grease on any metal to carbon interface, including headset. Also

use grease on metal to metal interface of threaded BB.

• After the first few rides and all the components are broken in and settled

into place, go through and re-torque all pivot axles and fasteners. After

this first adjustment, you will be ready to rip for the long haul.

1

5 6 7 8 9 10 11 12 13 14 15

16 17

18

19

20

2

3

4

21

22

23