EN-23

48619852_ed3

EN

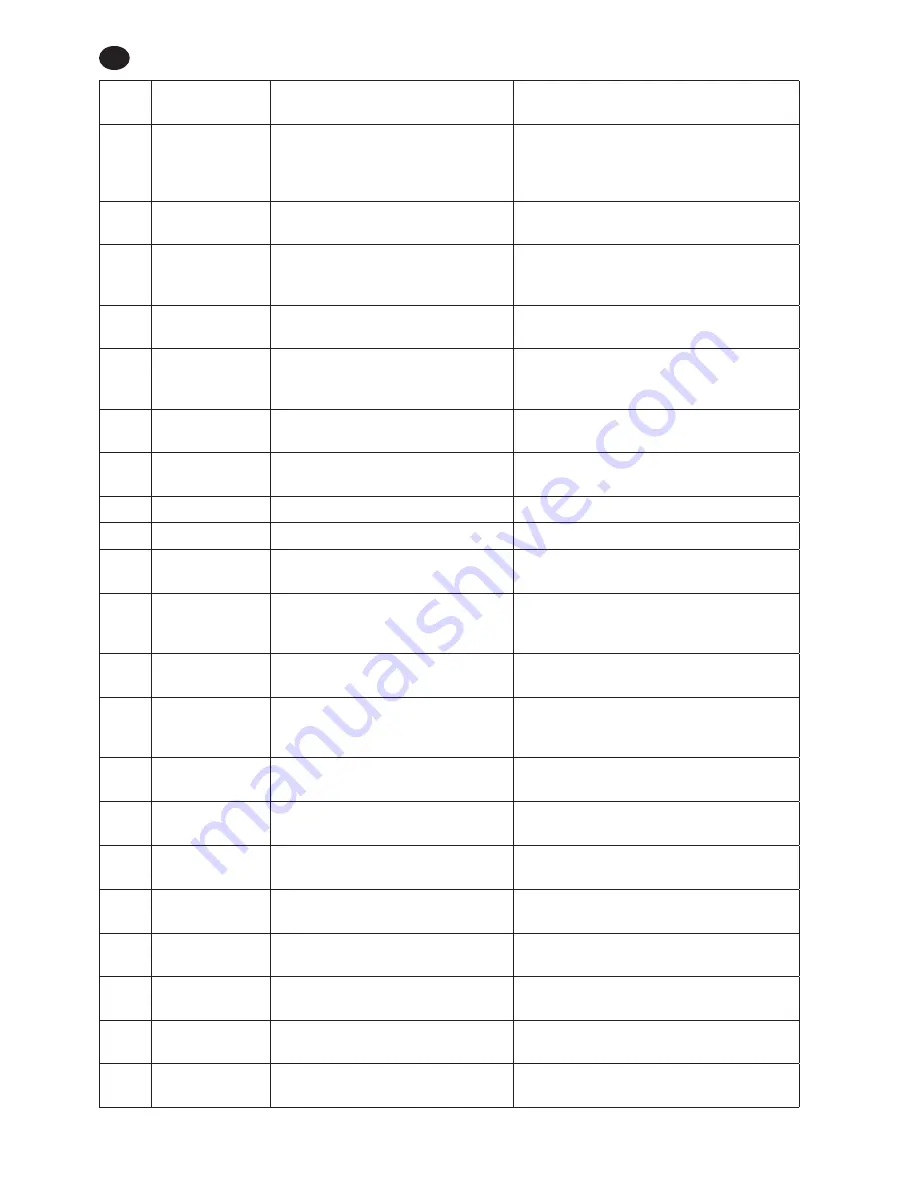

Fault

Code

Category

Notes

Actions/Solutions

E-0F

Motor Controller Fault

Under Torque.

Torque low limit is too high or the user

released the trigger before the cycle was

complete. The user should keep the trigger

engaged until the cycle is complete.

E-1B

Motor Controller Fault Battery Cell Fault (detected by Motor

Controller).

Tool did not run all steps.

E-1C

Motor Controller Fault

Low Battery Fault.

The tool will still operate properly. This is a

warning that the battery voltage is almost

drained. Replace or re-charge the battery.

E-1D

Motor Controller Fault Critical Battery Fault (detected by

Motor Controller).

Battery voltage critically low.

E-1E

Motor Controller Fault

Motor controller is going to sleep due

to idle timeout (Fault is ONLY displayed

if the tool is connected via USB).

Pull trigger to power-up tool.

E-1F

Motor Controller Fault Wakeup Code received (but not

expected)

Tool wakeup.

EE-E0

RF Protocol Error

RF Protocol Error - RF Message Packet

too small.

RF message packet too small.

EE-E1 RF Protocol Error

RF Protocol Error - RF Packet too long.

RF packet too large.

F-01

Trigger Fault

Trigger was pulled while tool is disabled. ICS, PCM, or tool display needs to enable the tool.

F-02

Trigger Fault

Trigger was pulled during a configured

delay period between cycles.

Wait for configuration delay and pull trigger again.

F-03

Trigger Fault

Smart Socket function has the tool

locked until PCM indicates the correct

socket has been attached to the tool.

Attach the correct socket for the selected

configuration.

1-FF

Tool Communication

Error

USB enumeration fault.

Bad Command received by Communication

Interface (USB or Wireless).

10-01

Tool Event

Configuration Page Update from

Communication interface (USB or

Wireless).

Configuration is updated from external

communication.

10-02

Tool Event

Tool Locked by Communication

Interface (USB or Wireless).

Tool locked from external communication.

10-03

Tool Event

Tool disabled by Communication

Interface (USB or Wireless).

Tool disabled.

10-04

Tool Event

Configuration Selected by Communication

Interface (USB or Wireless).

Configuration selected from external

communication.

10-05

Tool Event

Gang Advanced by Communication

Interface (USB or Wireless)

Gang advanced.

10-06 Tool Event

Gang reset by Communication

Interface (USB or Wireless).

Gang reset.

10-0

Tool Event

Configuration advanced by

Communication Interface (USB or Wireless).

Configuration advance.

10-08

Tool Event

Configuration Reset by Communication

Interface (USB or Wireless).

Configuration reset.

10-09

Tool Event

SPI Memory erased by Communication

Interface (USB or Wireless).

SPI Memory erased.

RELEASED 18/Apr/2014