EN-21

48619852_ed3

EN

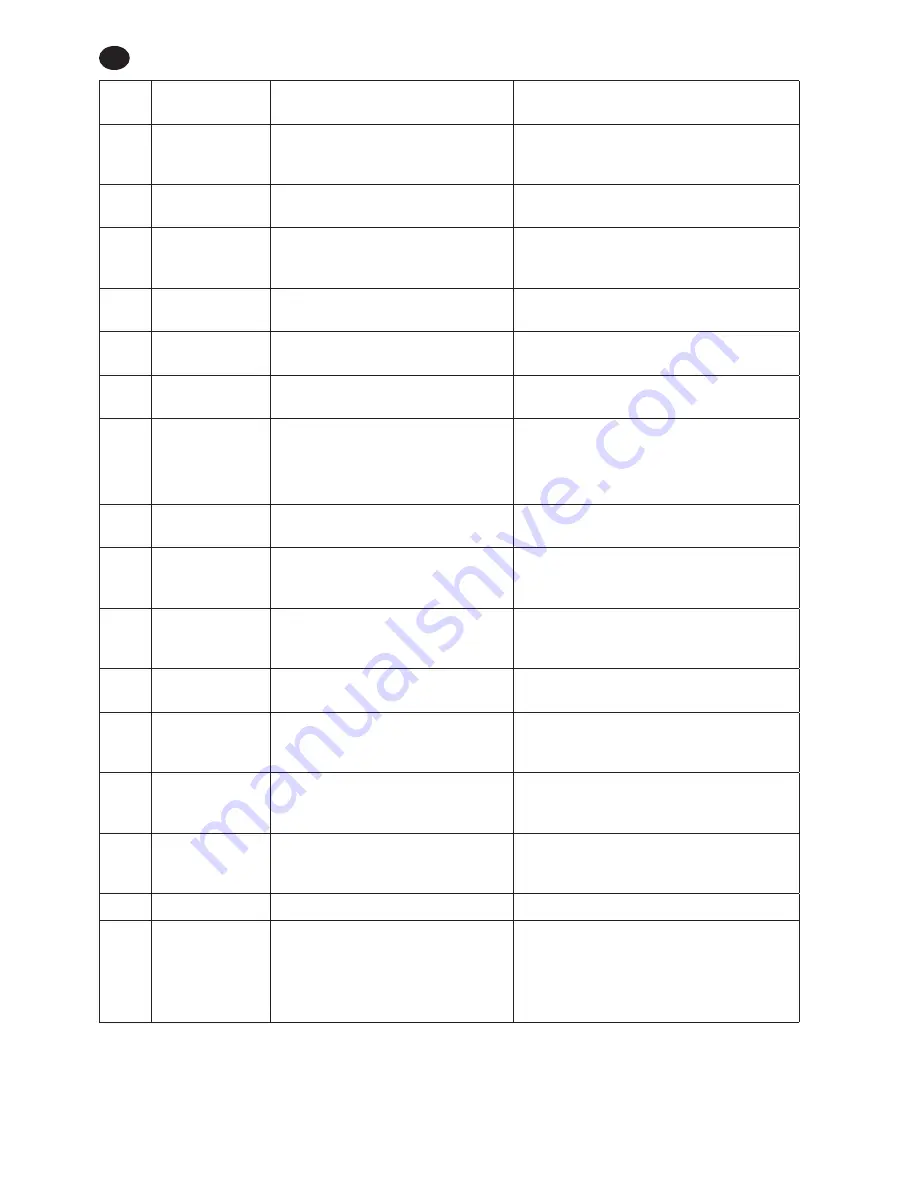

Fault

Code

Category

Notes

Actions/Solutions

C-09

Configuration Fault

Current Torque Low Limit is greater

than Current Torque High Limit (Fault

code to be removed).

Invalid Torque lo limit value is programmed.

Program the Torque lo limit from ICS.

C-10

Configuration Fault Tool configuration step is not set for

either Angle or Torque.

Invalid configuration is programmed.

Program configuration from ICS

C-11

Configuration Fault

Current Threshold value is greater

than maximum tool torque OR Current

Threshold value is less than 0.

Invalid Threshold value is programmed.

Program Threshold value from ICS.

C-12

Configuration Fault Current Free Speed is greater than

maximum motor speed.

Invalid Free speed value is programmed.

Program Free speed value from ICS.

C-13

Configuration Fault Current Shiftdown Speed is greater

than maximum motor speed.

Invalid Shift down speed value is programmed.

Program Shift down speed value from ICS.

C-14

Configuration Fault Current display unit value is

unsupported.

Programmed display unit is not supporting currently.

Program Display unit as Nm, In-Lbs, Ft-Lbs or dNm.

C-15

Configuration Fault

Current Shiftdown Point if above

target or above Target (for torque

strategy) or above tool’s torque limit

(for angle strategy).

For Angle strategy, program Shift down point

less than target torque.

For Torque strategy, program shift down point

less than tool’s max torque.

C-16

Configuration Fault Number of configuration steps is set to 0.

Invalid configuration is programmed.

Program configuration from ICS.

C-0A

Configuration Fault

Current Angle High Limit is greater

than Tool’s maximum Angle value (to

be set to 9999).

Invalid Angle hi limit value is programmed.

Program the Angle hi limit from ICS.

C-0B

Configuration Fault

Current Angle Low Limit is greater

than Tool’s maximum Angle value (to

be set to 9999).

Invalid Angle lo limit value is programmed.

Program the Angle lo limit from ICS.

C-0C

Configuration Fault Current Angle High Limit is less than

Current Angle Low Limit.

Invalid Angle hi limit value is programmed.

Program the Angle hi limit from ICS.

C-0D

Configuration Fault

Current Angle Low Limit is greater

than Current Angle High Limit (Fault

code to be removed).

Invalid Angle lo limit value is programmed.

Program the Angle lo limit from ICS.

C-0E

Configuration Fault

Tool configuration step is a Torque

target and target value is outside

torque high and low limits.

This is applicable for Torque Configuration

step only. Invalid target torque is

programmed. Program target torque from ICS.

C-0F

Configuration Fault

Tool configuration step is an Angle

target and target value is outside

angle high and low limits.

This is applicable for Angle Configuration

step only. Invalid target angle is programmed.

Program target angle from ICS.

E-00

Motor Controller Fault

Battery Fault.

Replace battery.

E-01

Motor Controller Fault

Invalid Hall State.

Faulty HALL cable. Contact the IR Service

Center for service.

Check wireless settings using ICS to ensure

that tool’s RF settings match with PCM. Also

confirm that the tool’s ID is in the PCM’s list.

RELEASED 18/Apr/2014