ALTERNATE LUBRICANTS.

You may use a petroleum-based

lubricant that is premium quality, does not contain detergents,

contains only anti-rust, anti-oxidation, and anti-foam agents as

additives, has a flashpoint of 440°F (227°C) or higher, and has

an auto-ignition point of 650°F (343°C) or higher.

See the petroleum lubricant viscosity table below. The table is

intended as a general guide only. Heavy duty operating

conditions require heavier viscosities. Refer specific operating

conditions to your dealer for recommendations.

Temperature Around Unit

Viscosity @ 100°F

(37.8°C)

Viscosity Grade

°F

°C

SUS

Centistoke

s

ISO

SAE

40 & below

4.4 & below

150

32

32

10

40 - 80

4.4 - 26.7

500

110

100

30

80 - 125

26.7 - 51.0

750

165

150

40

If you use a petroleum-based compressor lubricant at start-up

and decide to convert to All Season Select synthetic compressor

lubricant later on, the compressor valves must be thoroughly

decarbonized and the crankcase must be flushed before

conversion.

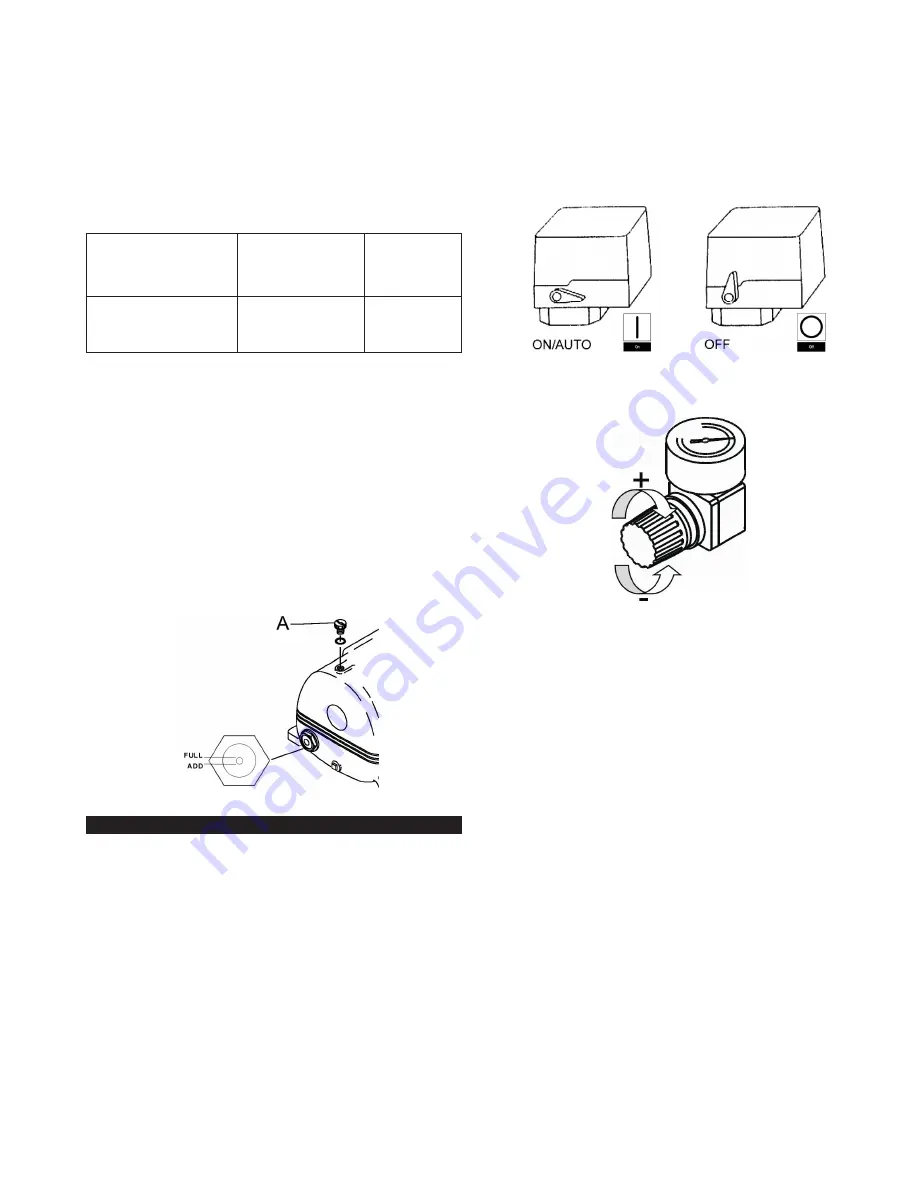

COMPRESSOR PUMP FILLING PROCEDURES:

•

WARNING

HAZARDOUS VOLTAGE. Can cause serious

injury or death. Disconnect power and

Lockout/Tagout machine.

1.

Unscrew and remove the oil fill plug (A).

2.

Slowly fill the crankcase with lubricant until the lubricant reaches

the “full” level of the sight glass as shown. Crankcase capacity is

one (1) pint (0.5 liters).

3.

Replace the oil fill plug HAND TIGHT ONLY.

OPERATION

GENERAL ________________________________________

Your air compressor was designed for 100% continuous duty

operation with the use of All Season Select synthetic compressor

lubricant and 60% continuous duty operation with the use of

petroleum lubricant. In other words, synthetic lubricant allows the

compressor to pump continuously without cycling. Petroleum

lubricant limits the compressor to a maximum of 36 minutes of

pumping time per hour. The compressor should not cycle more

than 10 times per hour.

NORMAL START-UP _______________________________

1.

Set the pressure switch lever to “OFF”.

2.

Close the regulator by turning it fully counterclockwise (-).

3.

Attach hose and accessory.

4.

Move the pressure switch lever to “ON/AUTO”. The unit will start.

5.

Allow tank pressure to build. The motor will stop when tank

pressure reaches cut-out pressure.

6.

Adjust the regulator to the desired secondary pressure by turning

it clockwise (+) to increase the pressure or counterclockwise (-)

to decrease the pressure.

NOTE:

When the receiver tank pressure drops below the

factory pre-set minimum, the pressure switch

resets and restarts the unit.

SHUTDOWN ______________________________________

1.

Set the pressure switch lever to “OFF”.

2.

Close the service valve fully.

3.

Remove the air tool or accessory.

4.

Slowly open the service valve to bleed air pressure down to 20

psig.

5.

Slowly open the manual drain valve at the bottom of the tank to

drain all condensate (water).

6.

Close the drain valve and the service valve for the next use.

7.

Wrap the power cord firmly around the handle.

8.

Store the unit indoors.

Filling Procedures

Pressure Switch Lever

Regulator

3

http://air.irco.com

P1.5IU-A9