16575128_ed2

5

Press the Bevel Pinion Bearing (39) over the threaded end and

onto the Bevel Pinion Driver (31).

NOTICE

If the Pinion (40) needs to be replaced, replace both the

Pinion and the Bevel Gear. They are a matched set and

cannot be matched with other Bevel Gears.

b. Check the Pinion for worn or broken teeth.

c. Screw the Pinion onto the Bevel Pinion Driver and tighten to

14 to 19 ft-lb (19 to 26 Nm) torque.d.

Coat the inner surface of the Arbor Coupling (42), the spline

of the Rotor (26) and the spline of the Bevel Pinion Driver with

3 to 4 cc of

Ingersoll Rand

No. 68 Grease.

Do not substitute

any other grease.

e. Install the Arbor Coupling onto the spline end of the Bevel

Pinion Driver.

f. Install the Thrust Spacer (38) over the Arbor Coupling (42) until

it is against the Bevel Pinion Bearing.

2. Grasp the Angle Arbor Housing (43) horizontally in leather-

covered or copper-covered vise jaws.

3. Slide the assembled Bevel Pinion Driver into the Angle Arbor

Housing.

4.

For Model 77A45W109, 77A60W107, 77A60P107, 77A60P109

or 77A75P107,

next install the Motor Spacer (41).

NOTICE

Make sure the Throttle Lever Assembly (17) mounting boss

on the Throttle Handle (1) aligns with the I-R logo on the

exterior of the Angle Arbor Housing.

NOTICE

For Model 77A25F107, make sure the spline on the Rotor (26)

properly engages the spline in the Rotor Pinion (35).

5. Slide the assembled Throttle Handle into the Angle Arbor

Housing.

6. Clean the Coupling Nut (21) threads and carefully apply a uniform

coat of Vibra-Tite® * * VC3 No. 205 to at least the first three

threads. Allow the Vibra-Tite to cure for ten to twenty minutes

before assembly.

CAUTION

Do not exceed 52.5 ft-lb (71.2 Nm) torque. The motor may be

damaged if this torque is exceeded.

7. Using the No. 77H-281 Coupling Nut Wrench, install the Coupling

Nut and tighten it between 48 to 52.5 ft-lb (64 to 71 Nm) torque.

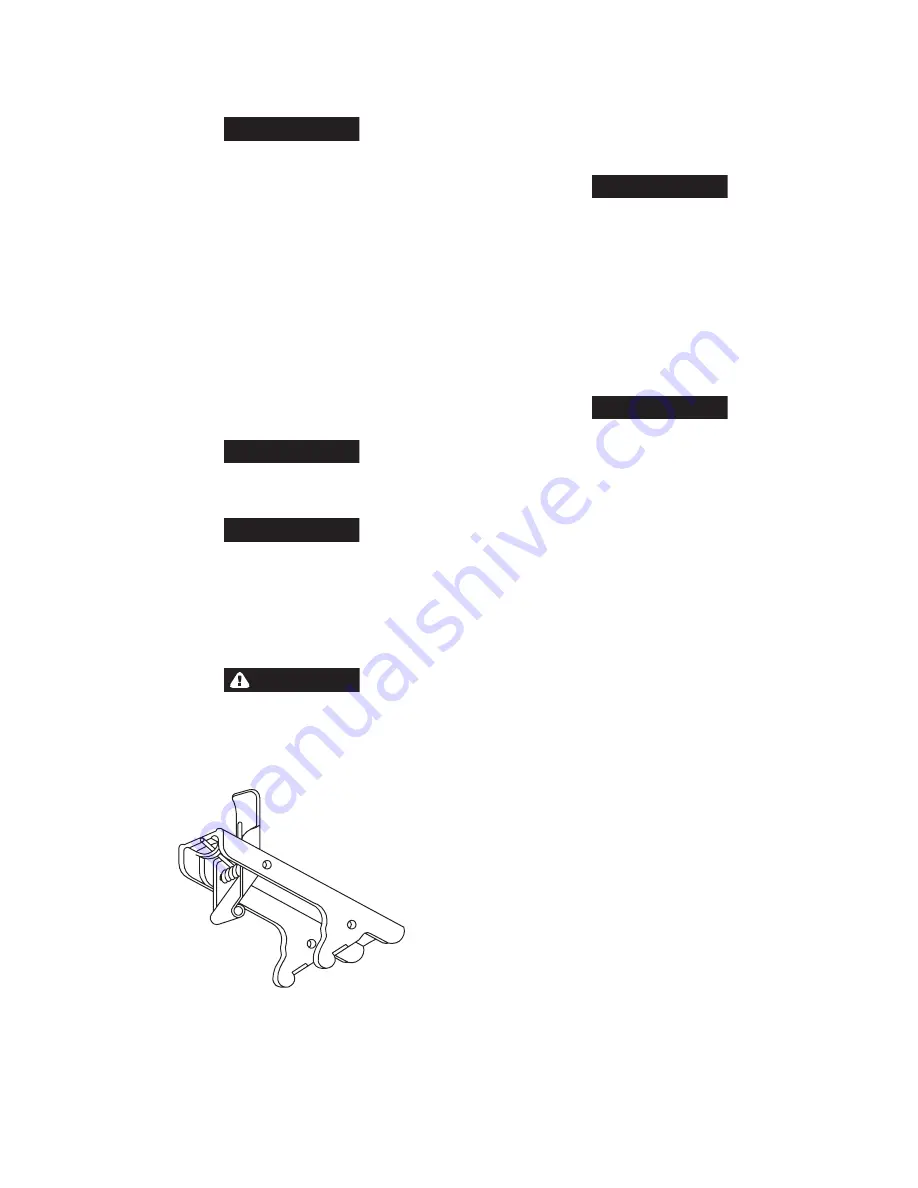

Assembly of the Throttle Lever and Inlet

Locking Lever Assembly

(Dwg. TPD662)

Assemble the Throttle Lever Assembly (17) as illustrated.

Align the holes in the Throttle Lever Assembly (17) with the slots

in the Throttle Handle. Using a soft hammer, tap the Throttle Lever

Pin (16) into the Throttle Lever Assembly until it slightly protrudes

from the opposite end. File off any sharp edges. Operate the

a.

b.

1.

2.

mechanism to assure operation.

Grasp the flats of the Throttle Handle Assembly (1) in leather-

covered or copper-covered vise jaws, air inlet up.

Insert the Throttle Valve Spring (6), small end first, into the Handle.

** Registered trademark of ND Industries.

NOTICE

The Inlet Bushing (4) has an interference thread. Apply a light

film of oil to the threads before assembly.

5. Clean the face of Inlet Bushing (4) and the Inlet Bushing

Screen (5) with a suitable cleaning solution and allow to dry.

Insert the parts into the end of the Throttle Handle. Tighten the

Inlet Bushing to 125-26 ft-lb (170-35 Nm) torque.

Assembly of the Angle Head

For Model 77A60P107, 77A60P109 or 77A75P107:

Install the Lower Arbor Spring Washer (51) onto the Depressed

Center Wheel Arbor (60).

Press the Arbor Lower Bearing (50) onto the Depressed Center

Wheel Arbor until it contacts the Lower Arbor Spring Washer.

NOTICE

If the Bevel Gear (40) is worn or broken, replace both the

Bevel Gear and the Pinion as they are a matched set and

cannot be matched with other Pinions.

3. Grasp the flats of the Depressed Center Wheel Arbor in leather-

covered or copper-covered vise jaws, arbor bearing end up.

Tighten the Bevel Gear to 8.5 to 11.5 ft-lb (11.5 to 15.5 Nm)

torque.

4. Install the Bevel Gear Spacer (49).

5. Clean the threads on the Arbor; apply a film of thread locking

compound to the threads. Screw the Bevel Gear Nut (48) onto

the Arbor and tighten to 8.5 to 11.5 ft-lb (11.5 to 15.5 Nm) torque.

Remove the Arbor from the vise.

6. Grasp the Angle Arbor Housing (43) in leather-covered or copper-

covered vise jaws, angle head up. Install the Upper Bearing Spring

Washer (46) and Upper Arbor Bearing (47).

7. If replacement of the Mounting Plate Pin (45) is necessary, press a

new pin into the Angle Arbor Housing.

8. Install the assembled Depressed Center Wheel Arbor into the

Angle Arbor Housing.

9. Place the Depressed Center Wheel Guard (59) in position on the

Angle Arbor Housing, making sure the Mounting Plate Pin aligns

with the pin hole in the guard.

10. Install the Screw Lock Washers (53) and Guard Screws (54).

Tighten to 7.5 to 8 ft-lb (10 to 11 Nm) torque.

11. Slide the Autobalancer Assembly (61), rectangular hub side

leading, onto the Arbor.

12. To mount the wheel on the tool, proceed as follows:

For Type 27 and Type 28 Plain Hole Mounted Wheels:

Thread the Depressed Center Wheel Flange (66 or 68) onto the

Arbor against the Auto balancer Assembly.

Slide the wheel onto the Arbor against the Depressed Center

Wheel Flange.

Thread the Depressed Center Wheel Nut onto the Arbor

against the wheel and tighten the Nut using the Depressed

Center Wheel Spanner Wrench (Part No. D32-26). Tighten the

Nut only enough to drive the wheel and prevent slippage.

Using a hex wrench, install the Wheel Retaining Screw (65) in

the end of the Arbor.

For Type 27 Mounted Wheels:

Install two Depressed Center Wheel Spacers (63) on the Arbor

against the Auto balancer Assembly.

Thread the wheel onto the Arbor.

Using the hex wrench, install the Wheel Retaining Screw (65)

in the end of the Arbor.

3.

4.

1.

2.

a.

b.

c.

d.

a.

b.

c.