- Check pneumatic system (visual inspection)

Orientation

To ensure trouble-free operation, periodic checks (visual inspection) of the

pneumatic system are necessary.

- Check system pressure and sealing air settings.

- Check supply and fluid lines.

- Check silencers.

- Drain condensate (not applicable to auto-drain).

- Check pressure setting on the pressure differential monitoring pressure gauge.

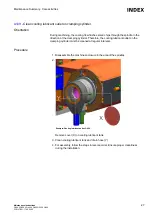

Example: Pneumatic maintenance unit G420 (by FESTO)

Due to different requirements and/or specifications of the respective

manufacturers, be sure to review the respective manufacturer's

documentation!

The following components are used on the system maintenance unit (X) and the

extension for sealing air on the glass scales (Y) :

- X System maintenance unit

- 1. Switch-on valve (manual)

- 2. Pressure regulating valve (with filter) system pressure 6 bar

- 3. Pressure gauge for system pressure

- 4. Filter insert (filter fineness 40 µm)

- 5. Filter with automatic condensate drain

- 6. Filter insert (filter fineness 5 µm)

- 7. Branch module

- 8. Pressure sensor for system pressure

- 9. Silencer

- 10. Electrically actuated switch-on valve

-

-

-

Maintenance Summary - Care activities

13

Maintenance Instructions

G300.2 G320.2 G400.2 G420 G500.2 G520

DIE147EN - 17.08.2022