18

Transportation, Installation, Commissioning

LL1602.10043 - 04.08.2014

ABC

PREPARATIONS

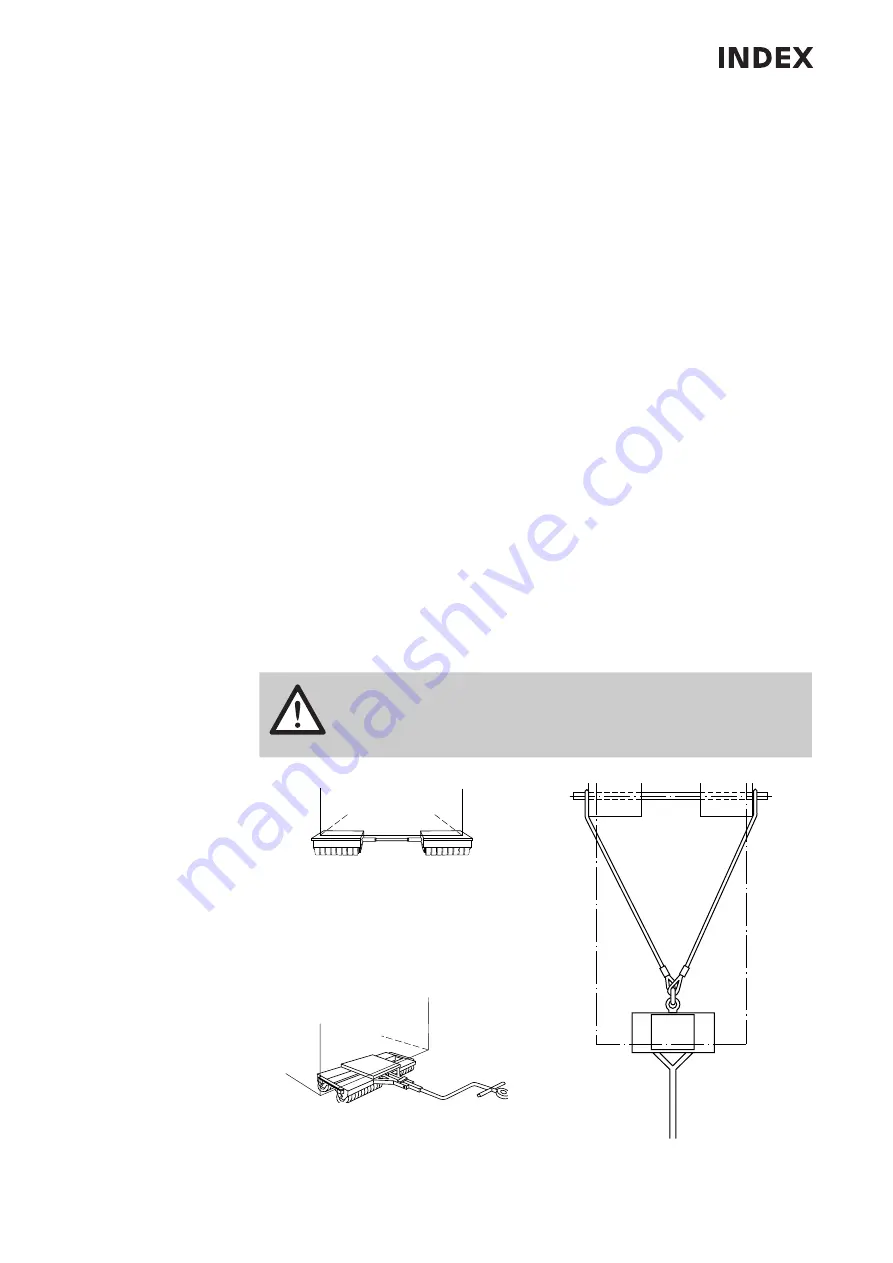

Transportation with casters

077001.0277

077001.0276

Transportation with casters

Use transportation casters when there is no suitable crane, a mobile crane or when

a fork lift truck cannot be used at the installation site.

The advantage of casters is the low loading height which allows loading and un-

loading the machine using a hydraulic jack.

The disadvantages are the relatively small wheels (casters) which require a solid

smooth floor with appropriate load bearing capacity, transport is very slow and

must not be jerky.

Depending on the size of the machine two or three casters are needed, one of

which must be a swivel caster.

The load bearing capacity of the individual trolley may be less than the mass of the

machine.

When using 2 trolleys their load bearing capacity should be 2/3 of the machine

mass.

When using 3 trolleys the two rigid ones should be able to take at least 1/3, the

steerable one 2/3 of the machine mass.

Castor trolleys are placed under the short sides of the machine base. If the ma-

chine sits on planks, the transport rolls may also be pushed under them. Lower the

machine slowly until it rests on the castor trolleys as shown in the picture.

The casters must always run in parallel to the load, otherwise they will "rub" and

the coating of the castors will get damaged.

Connect the swivel caster and the fix ones with steel ropes

(Fig) to prevent them from moving apart.

Secure the load with suitable straps.