12

STZSkW ed 12/07

ZEUS Superior kW

Technical Documentation

Technical Documentation

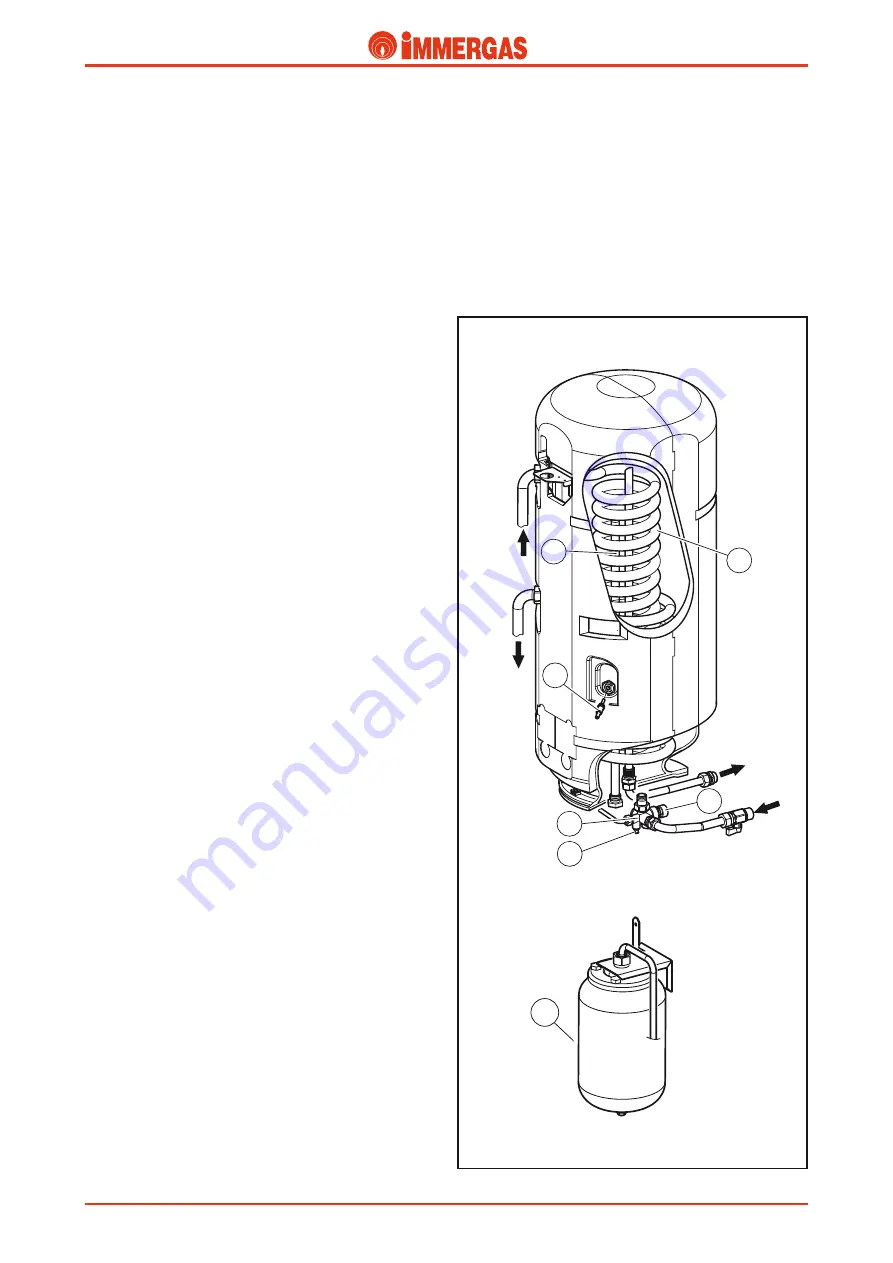

Storage tank.

It is a storage tank with coil and total capacity of 60 litres

(useful

54 litres)

built entirely out of stainless steel and is completely

insulated with self-extinguishing polystyrene.

It is made up of an external liner enclosed in the lower part by

a flange fixed using12 screws.

A stainless steel pipe (4) is located inside the tank, shaped like

a con centric spiral (coil) which develops through the lower

part of the boiler. The heat exchange between the hot water

in the primary circuit and the water in the storage tank takes

place through the coil surface.

This keeps the water in the storage tank at a constant tem-

perature and guarantees instantaneous production of DHW

whenever water is drawn.

If necessary, the coil can be removed from the storage tank after

the lower inspection flange has been removed.

Storage tank integrity and function are guaranteed by the

following devices:

Anode (1).

The anode is inserted in the storage tank and protects it against

corrosive actions of galvanic currents.

It is screwed onto the lower flange.

Polyphosphate dispenser

(optional).

The polyphosphate dispenser prevents the formation of scale

on the coil surface. The kit is assembled on domestic cold

water inlet pipe.

Recirculation kit

(option).

Recirculation kit allows for DHW recirculation system pipes

to be connected.

It consists in a pipe, which is inserted in the boiler after the

anode and relative plug have been removed.

When the kit is installed, the anode is screwed onto the end

of the pipe.

An additional kit is available

(option)

which includes a pump

for DHW recirculation system.

The kit is not protruding outside the boiler clearance while the

pump slightly extends beyond the plastic grille at the bottom

of the appliance.

DHW NTC probe (B2) (9).

The DHW probe allows integrated P.C.B. to read temperature

of water inside the storage tank.

It is secured to the external wall of the water tank and it is

inserted in an sample point.

Safety valve group (13).

The safety valve group is located in the lower part of the storage

tank near the domestic cold water inlet.

As well as an 8-bar valve (10) which prevents the storage tank

safety pressure from being exceeded, it includes:

- a filter, a 12 l/min flow limiter

(24 kW version and 28 kW

version)

and14 l/min

(32 kW)

, a storage tank draining valve

with hose union (12) and a one-way valve

(see hydraulic cir-

cuit paragraph, detail “5”)

in order to ensure that increased

pressure DHW does return toward water mains supply.

11

Domestic hot water expansion vessel (11).

DHW expansion vessel compensates for any variations in

volume caused by water in the storage tank.

It is connected to the safety valve group and has a 2-litre ca-

pacity with a 3.5-bar factory set pressure.

Coil flow

9

1

4

10

13

12

Cold

water

inlet

Hot

water

outlet

Coil return